Accordion

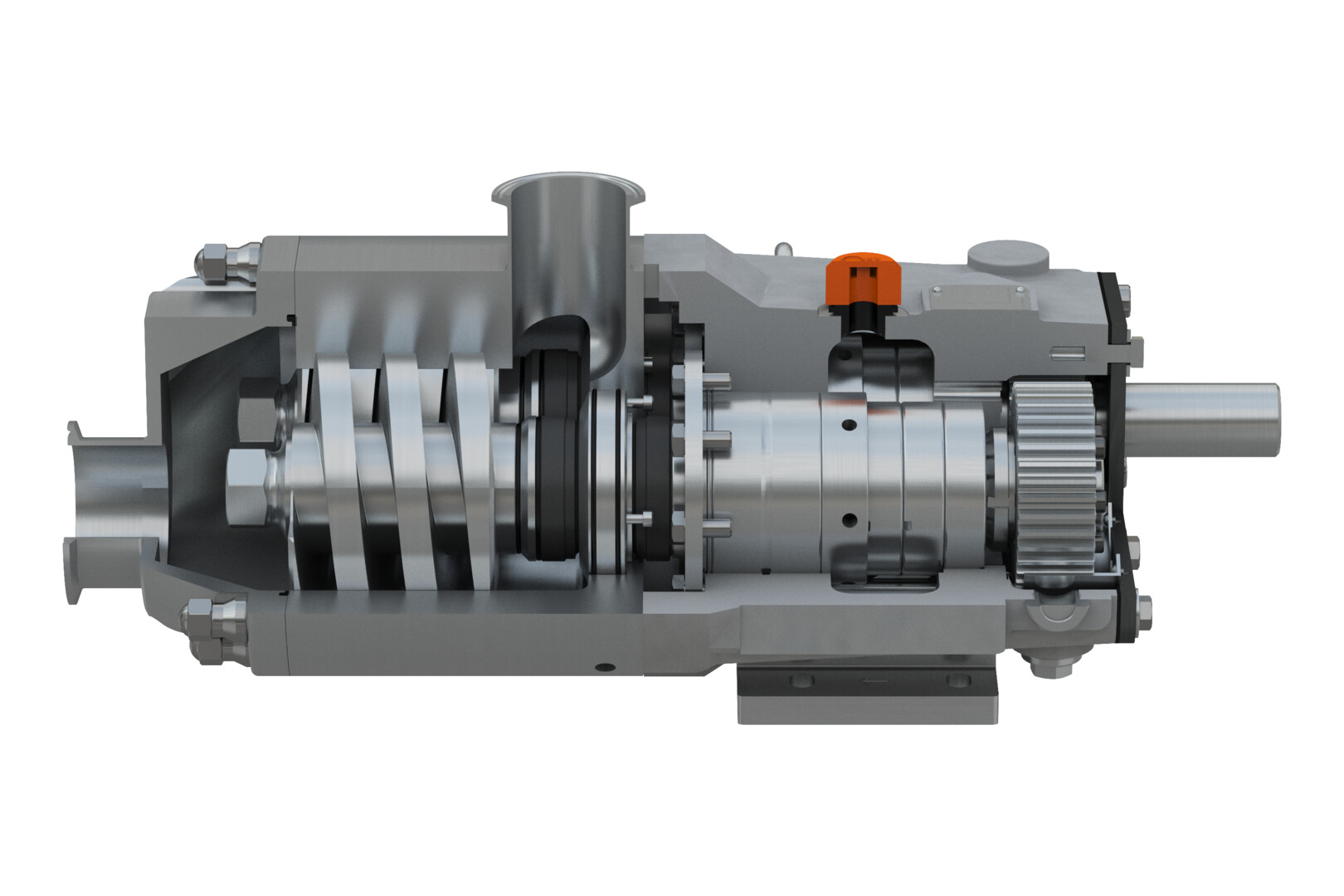

- Reliable performance: Screws made from Waukesha Alloy 88 non-galling material allow the pump to run through incidental contact, reducing the risk of damage.

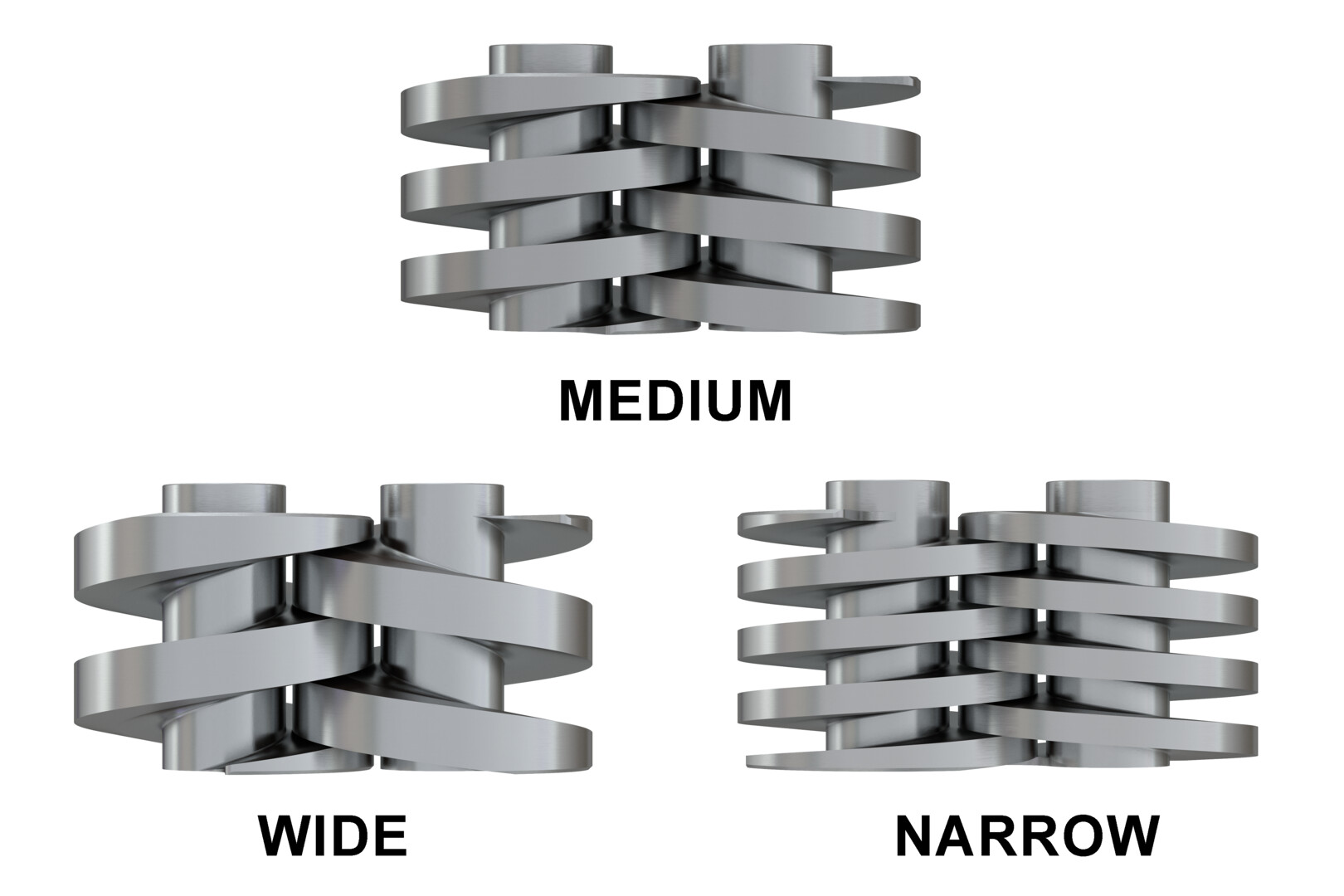

- Gentle product handling: Capable of pumping large particulates without degradation.

- Responsive service: Global distribution network with certified repair centers ensures quick access to parts and service.

- Reliable performance: Screws made from Waukesha Alloy 88 non-galling material allow the pump to run through incidental contact, reducing the risk of damage.

- Gentle product handling: Capable of pumping large particulates without degradation.

- Responsive service: Global distribution network with certified repair centers ensures quick access to parts and service.

- Reliable performance: Screws made from Waukesha Alloy 88 non-galling material allow the pump to run through incidental contact, reducing the risk of damage.

- Gentle product handling: Capable of pumping large particulates without degradation.

- Responsive service: Global distribution network with certified repair centers ensures quick access to parts and service.

Sep 1, 2026 @

SPX FLOW Margarine Seminar 2026

The objective of the seminar is to train the personnel in principles and practices of crystallization of fats and oils.

Register

Sep 30, 2026 - Oct 1, 2026

Anhydro Flavour Seminar

Current best practice of the spray drying plant, plant upgrades, and new product developments

Register

Jan 13, 2026 - Jan 15, 2026

Future Minerals Forum

Explore how SPX FLOW is shaping the future of mining and mineral processing at the Future Minerals Forum in Riyadh, Saudi Arabia. Discover innovative mixing, separation, and flow technologies designed for sustainability and performance across the global mining sector.

VIEW

Nov 18, 2025 - Nov 20, 2025

Metstrade 2025

Meet Johnson Pump Marine at METSTRADE 2025 in Amsterdam this November. Explore high-performance marine pumps for bilge, fuel, cooling, and mobile applications.

VIEW

Oct 29, 2025 - Oct 30, 2025

The Future of Protein Production

Our experts will explore the engineering and economic trade-offs between these two common reactor types, offering valuable insights for companies evaluating the best path to scale. Whether you're developing next-gen proteins or looking to optimize your existing fermentation process, visit SPX FLOW at the show to connect with our solution makers and discover how Lightnin® and Stelzer® technologies are advancing the future of protein production.

VIEW

Oct 23, 2025 - Oct 24, 2025

Scraping the Surface: Waukesha Cherry-Burrell SSHE Positioning & Applications

Join our webinar to learn about Scraped Surface Heat Exchangers (SSHE), including comparisons with plate and tubular technologies, and discover our SSHE portfolio and services for maximizing operational efficiency.

VIEW

Oct 21, 2025 - Oct 23, 2025

Engineering Training School – October Session

When an opportunity comes along to make your job easier and your customers happier – you seize it. Join us in Wisconsin this October for three days of engineering-focused training on APV and Waukesha Cherry-Burrell equipment where we’ll teach you best practices for designing the most efficient and sustainable process solutions possible From concept to implementation and procurement to training, this is one school you won’t want to miss.

VIEW

Sep 29, 2025 - Oct 1, 2025

Pack Expo Las Vegas

Join our team at Pack Expo Las Vegas 2025, where in booth #N-5164 we’ll showcase our latest innovations in the sanitary processing sector.

VIEW

Sep 29, 2025 - Oct 1, 2025

WEFTEC

Join our team at Weftec 2025 in Chicago, Illinois. During the event, we’ll showcase our industry-leading anti-ragging impeller technology and gear boxes designed for rugged applications with live demonstrations and presentations featuring our solution makers. Free registration is available and we’re already taking appointments to address your application questions. We’ll see you in Chicago, #2854.

VIEW

Sep 25, 2025 @ 7:00 AM GMT GMT

Built to Last: The U2 ND Positive Displacement Pump Advantage

Learn how the Waukesha Cherry-Burrell® U2 ND positive displacement pump solves tough industrial challenges like viscosity, corrosion and slurries. Register today for this complimentary webinar.

VIEW

Sep 5, 2025 @ 1:00 PM GMT GMT

Built to Last: The U2 ND Advantage - EMEA

Learn how the Waukesha Cherry-Burrell® U2 ND pump solves tough industrial challenges like viscosity, corrosion and slurries. Register today for this complimentary webinar.

VIEW

Aug 26, 2025 @

Built to Last: The U2 ND Advantage - AMER

Whether you're facing pump failures, high maintenance or chemical wear, this webinar will show how the U2 ND pump can deliver long-term value across your operation.

WATCH

Jul 8, 2025 - Jul 9, 2025

Service That Moves, Pump Care Services Overview

Discover how Bran+Luebbe Pump Care Services help maximize pump performance and uptime with expert field support, factory repairs and diagnostics.

VIEW

May 28, 2025 @ 8:00 AM GMT

Tubular UHT Systems

Join SPX FLOW's Tubular UHT solution maker and technology expert, Serafin Garcia, for an insightful webinar focused on creating nutritious beverages with and without particulates via an upgraded modular Tubular UHT System. Our enhanced modular design enables customized solutions with pre-engineered modules, tailored specifically to your operational needs and streamlining your process from start to finish.

VIEW

May 20, 2025 - May 22, 2025

Nordic Dairy Congress

Make the most of your time at the Nordic Dairy Congress by scheduling and one-on-one meeting with one of our solution makers. Whether you have specific application challenges or want to explore our latest innovations, we're here to help.

VIEW

May 20, 2025 @ 11 AM EST

Reliability Never Sleeps, , Turning Insight into Uptime with an MMR

Get insights on aging equipment, obsolete gearboxes, and how to avoid costly inventory surprises.

VIEW

May 20, 2025 - May 22, 2025

Engineering Training School – May Session

When an opportunity comes along to make your job easier and your customers happier – you seize it. Join us in Wisconsin this May for three days of engineering-focused training on APV and Waukesha Cherry-Burrell equipment where we’ll teach you best practices for designing the most efficient and sustainable process solutions possible From concept to implementation and procurement to training, this is one school you won’t want to miss.

VIEW

May 19, 2025 - May 22, 2025

ALTA 2025, a mining conference in Australia

ALTA 2025 is a world-class annual mining and metallurgical processing conference, and a leading platform for innovation. The carefully crafted program is practically oriented rather than academic, and the themes running through the conference reflect key current and developing technology trends.

VIEW

Apr 30, 2025 - May 1, 2025

Innovative Dairy Processing Solutions for a Changing Industry

Discover how we’re shaping the future of dairy processing with a four-part webinar series reviewing top considerations to maximize your dairy processing.

VIEW

Apr 15, 2025 - Apr 17, 2025

CheeseCon 2025

Join our team at CheeseCon 2025, booth #703. Come talk to the Dairyland solution makers bringing years of dairy processing experience to help solve your biggest challenges. Come see our Universal 3 positive displacement pump, a quick ship product, ensuring uptime by shipping in 10 days or less from order date. Our Grade A dairy compliant mixproof valves have been reliably serving dairies across America for years, stop by and see our impressive 8” valve body on display.

VIEW

Feb 26, 2025 @ 10:00 AM EST EST

Ultra High Temperature (UHT) Systems: It’s All About Taste

Discover how APV® UHT Systems preserve flavor, texture and nutrition while optimizing efficiency, sustainability and shelf life for dairy and plant-based beverages.

WATCH

Feb 6, 2025 @ 11:00 AM EST EST

980 Series, a Mixer as Tough as the Industry It Serves

Discover how this advanced solution sets a new standard for reliability and performance in demanding chemical and mining applications. What's more, expand your capabilities with custom options, tailoring the Lightnin 980 Series mixer to your specific needs.

WATCH

Nov 6, 2024 @ 11:00AM EST EST

Scraping the Surface: SSHE Positioning & Applications

Join us for an informative webinar on Scraped Surface Heat Exchangers (SSHE), where we will explore critical factors in choosing SSHEs over plate or tubular technologies.

WATCH

Oct 22, 2024 - Oct 24, 2024

Engineering Training School (October 2024)

Join us in Wisconsin this October for three days of engineering-focused training on APV and Waukesha Cherry-Burrell equipment where we’ll teach you best practices for designing the most efficient and sustainable process solutions possible.

VIEW

Oct 10, 2024 @ 11:00 AM EST

Getting It Right: Properly Sizing Your Positive Displacement Pump

Join us for a webinar focused on the proper sizing of a positive displacement pump.

WATCH

Sep 11, 2024 @ 11AM EST

Importance of Using a True Drywell

In this webinar event you will learn the value of a true drywell and why the lesser technologies are not equal.

WATCH

Jul 25, 2024 @ 8:00AM GMT

The Secret Scoop

During the session our expert solution maker Pranav Shah will discuss designing a sustainable end-to-end ice cream processing line that saves energy, water and materials without compromising on premium product quality.

WATCH

Jun 27, 2024 @ 8:00AM GMT

Value to the Last Drop: Revolutionize Your Dairy Production with Advanced Milk Fractionation

We will discuss the value milk fractionation can bring to you and the key technologies used in the process to achieve efficient and sustainable production.

WATCH

Jun 18, 2024 @ 9:00 AM EST

Sustainable Plant-Based Processing: Fermentation, Ice Cream and Ingredients

In our final chapter of plant-based processing, we’ll focus on fermentation, ice cream and ingredients.

WATCH

Feb 22, 2024 @ 10:00 AM EST

How to Build Sustainability into Your Plant-Based Processes – Heat Exchange

Join us virtually as host Samuel Glover introduces how to build sustainability into plant-based beverages process lines.

WATCH

Jan 25, 2024 @ 10:00 AM EST

How to Build Sustainability into Your Plant-Based Processes – Homogenization

Join us virtually as host Con O’Driscoll introduces how to build sustainability into plant-based beverages.

WATCH

Dec 15, 2023 - Dec 14, 2023

Plant-Based: Mixing

Join us virtually as host Ulla Skytte introduces how to build sustainability into plant-based process lines.

WATCH

Nov 30, 2023 - Nov 29, 2023

Coast into Winter: Live Boat Prep for the Chilly Season

Get your boat winter-ready! Join our marine experts to learn the essential winterization steps for your pump equipment and maintenance hacks to ensure a smooth spring season ahead.

WATCH

Nov 22, 2023 - Nov 21, 2023

Plant-Based: Extraction

Join us virtually as host Thomas Leroy introduces how to build sustainability into plant-based beverages process lines.

WATCH

Oct 26, 2023 @ 2:00 PM CEST

Plant-Based: Designing the Process Line

Join us virtually as host Pranav Shah introduces how to build sustainability into plant-based process lines.

WATCH

Sep 14, 2023 @ 11:30 AM IST

Heat Transfer within a Stirred Tank

Heat transfer within a stirred tank occurs through conduction, convection of radiation.

WATCH

Jun 20, 2023 @ 1:30 PM GMT

Heat Transfer in Stirred Tanks (1)

Join us virtually as host Richard Cope, Ph. D, reviews the characteristics of heat transfer in stirred tanks.

WATCH

PRODUCTS

E3 Values

Gentle product handling: Capable of pumping large particulates without degradation. Responsive service: Global distribution network with certified repair centers ensures quick access to parts and service.