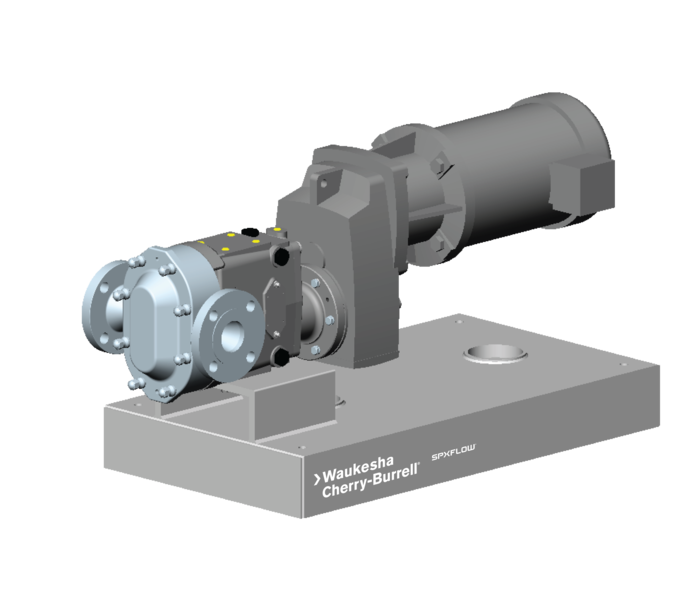

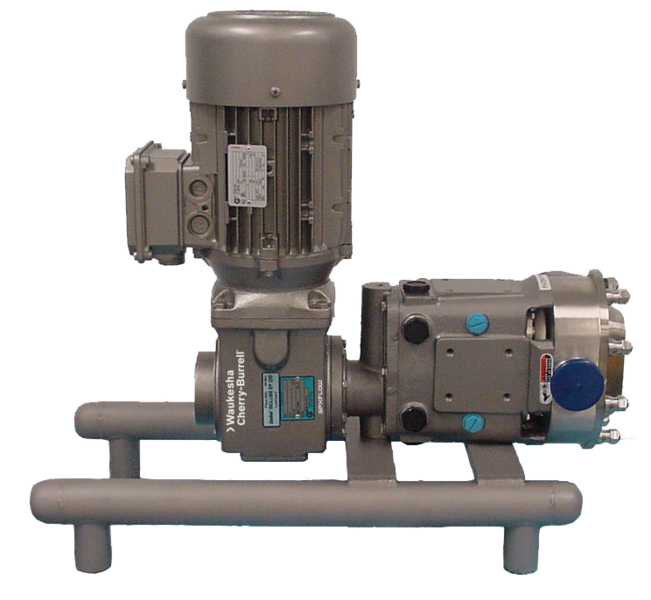

Universal Series - Tru-Fit® - Positive Displacement Pumps

Tru-Fit models are available for U1, U2, U3, Lobe, Twin Screw (UTS) and 5000 positive displacement pumps. Tru-Fit pump model advantages include: No shaft alignment necessary, no coupling guard required and ease of maintenance.