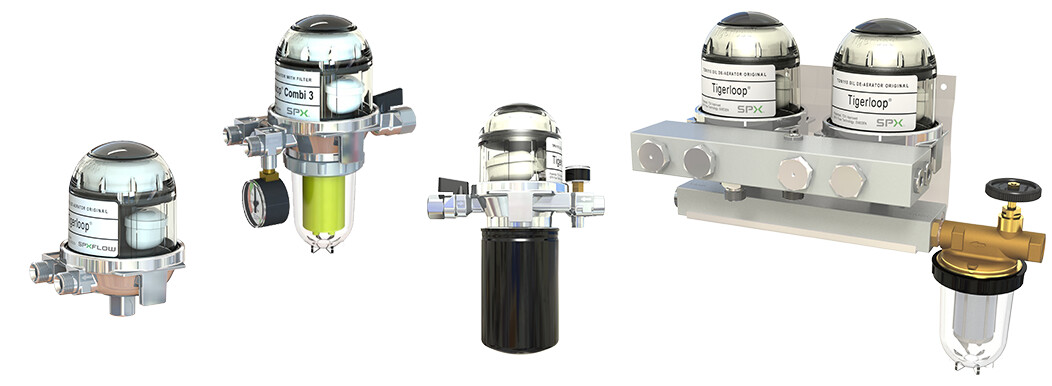

Tigerloop makes a one-pipe system possible for all types of oil heating installations helping to ensure environmental safety, cost-effectiveness and reliability.

Features

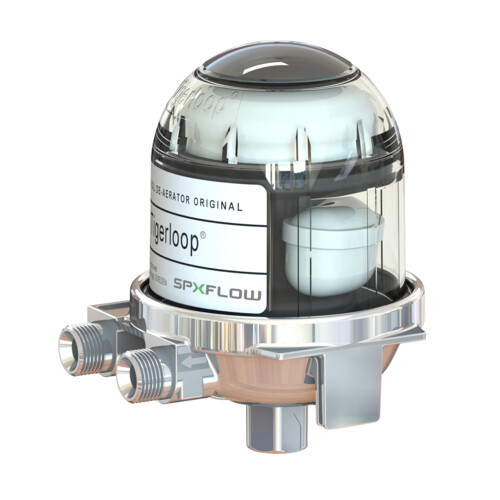

The improved original, third-generation automatic oil de-aerator. The innovation presented by Tigerholm in 1971 has for over 30 years made oil heating installations more efficient, safe and environmentally friendly. To be combined with a separate oil filter.

- Patented float system

- Unique built-in overpressure valve opens at 0.8 bar

- Protects equipment in the system (oil pump, oil hoses, etc.)

- High de-aeration capacity (8 l/h)

- High reliability

Technical Data

| Model | Pump connections | Tank connection |

| TON110I | 1/4" female thread | 1/4" female thread |

| TON110A | 3/8" male thread | 1/4" female thread |

| Technical data – Tigerloop® | |

| Max nozzle capacity | 110 l/h (29 GPH) |

| Max return oil pumped into the Tigerloop® | 120 l/h (32 GPH) |

| Max oil flow | 230 l/h (61 GPH) |

| Max de-aerating capacity | 8 l/h (2 GPH) |

| Max operating temperature | 60°C (140°F) |

| Max. / Min. operating pressure in feed line | +0,5 / -0,6 bar (+7.3 / -8.7 psi) |

The performance of the original Tigerloop®, with the convenience of an included, combined high-quality oil filter

Features

The New Tigerloop® Combi 3 offers several advantages thanks to the integrated shut-off valve for simple filter change and service. The integrated oil filter allows the possibility of choosing different oil filter inserts depending on the need. There is an optional integrated vacuum gauge for full control and easy troubleshooting. The installation is done with fewer connections simplifying the installation and reducing the risk for leakage.

- Convenient, all-in-one solution

- Includes a combined high-quality oil filter, integrated shut-off valve and optional vacuum gauge

- Possible to select different filter inserts depending on need

- Fewer installation connections with combined filter

- Less risk for leakage

- Easy to install

Technical Data

| Model | Pump connections | Tank connection |

| TC3 110I | 1/4" female thread | 3/8" female thread |

| TC3 110A | 3/8" male thread | 3/8" female thread |

| Technical data – Tigerloop® | |

| Max nozzle capacity | 110 l/h (29 GPH) |

| Max return oil pumped into the Tigerloop® | 120 l/h (32 GPH) |

| Max oil flow | 230 l/h (61 GPH) |

| Max de-aerating capacity | 8 l/h (2 GPH) |

| Max operating temperature | 60°C (140°F) |

| Max. / Min. operating pressure in feed line | +0,5 / -0,6 bar (+7.3 psi / -8.7 psi) |

The performance of the original Tigerloop® and Tigerloop® Combi 3, with addition of Tigerloop® Plus' included vacuum meter, shut-off valve and spin-on paper filter.

Features

The Tigerloop® Plus has been developed to meet the highest demands for cleaner, air-free oil. The smart, all-in-one design includes a vacuum gauge for full control and simple troubleshooting, a shut off valve for easy service and a Spin-on paper filter for the toughest filtration needs.

- Convenient, all-in-one solution

- Included spin-on paper filter, vacuum gauge and shut-off valve

- Fewer installation connections with combined filter

- Less risk for leakage

- Easy to install

- Extremely large filtration area of 1850 cm2 (287 in2)

- High filtration grade of 20 microns

Technical Data

| Model | Pump connections | Tank connection |

| TPN110I | 1/4" female thread | 1/4" female thread |

| Technical data – Tigerloop® | |

| Max nozzle capacity | 110 l/h (29 GPH) |

| Max return oil pumped into the Tigerloop® | 120 l/h (32 GPH) |

| Max oil flow | 230 l/h (61 GPH) |

| Max de-aerating capacity | 8 l/h (2 GPH) |

| Max operating temperature | 60°C (140°F) |

| Max. / Min. operating pressure in feed line | +0,5 / -0,6 bar (+7.3 psi / -8.7 psi) |

For larger capacity burners, the Tigerloop® Twin is an integrated, easy to install unit that provides double the de-aeration capacity of a standard Tigerloop.

Features

The Tigerloop® Twin is comprised of two units of standard Tigerloop conveniently connected in parallel and combined with a separate oil filter. The oil filter (tank connection) can be installed on either side of the unit. The Tigerloop Twin is for larger capacity burners up to 2000 kW.

- Double the de-aeration capacity in one easy to install, perfectly balanced unit

- Eliminate the risk of leakage in the return line

- Reduce the flow of fuel, preserve quality of oil

- Less dirt/sludge transported in the system

- Better combustion, reduces oil consumption

- Solve the problem of nozzle dripping causing soot build up

- Provides the best possible operating conditions for pump

- The installers save time and money (easier installation

- Tigerloop® is TÜV, UL and cUL approved

Technical Data

| Model | Pump connections | Tank connection |

| TWIN | 1/2" female threading | 3/8" female threading |

| Other connection sizes available upon request | ||

| Technical data – Tigerloop® | |

| Max nozzle capacity | 166 kg/hr / 200 l/h (366 lbs/hr / 83 GPH) |

| Max oil flow | 332 kg/h / 400 l/h (732 lbs/hr / 106 GPH) |

| Max de-aerating capacity | 16 l/h (4.2 GPH) |

| Max operating temperature | 60°C (140°F) |

| Max. / Min. operating pressure in feed line | +0,5 / -0,6 bar (+7.3 psi / -8.7 psi) |

| Filtration grade | 100 - 150 micron |