Automatic de-aerators for Automotive Industry

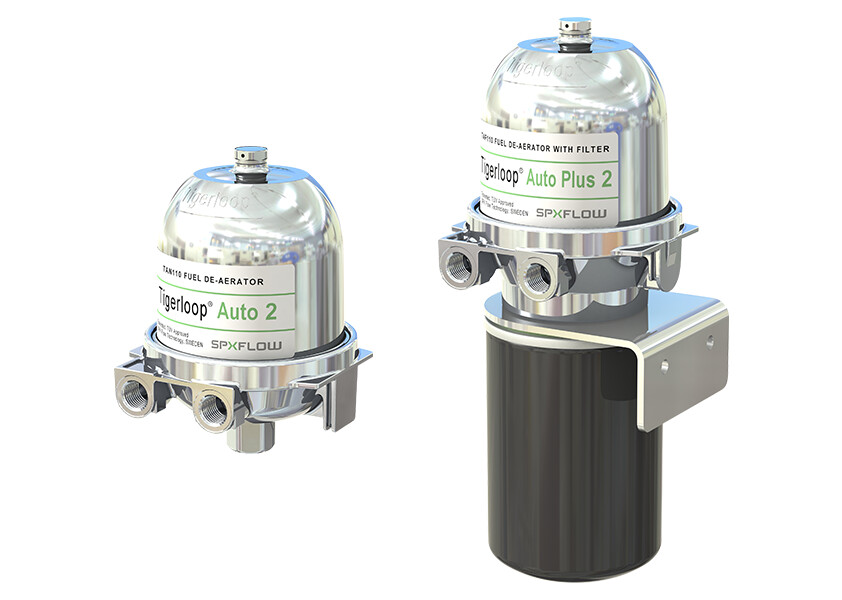

The Tigerloop® Auto 2 and Tigerloop® Auto Plus 2 are designed to meet the requirements of the Automotive Industry. The Tigerloop® Auto 2 models are suitable for auxiliary heaters and small diesel motors. The Tigerloop® Auto 2 models are compatible for use with diesel (EN590), biodiesel (EN14214) and HVO diesel (EN15940).

Tigerloop® makes a one-pipe system possible for almost all types of oil heating installations helping to ensure environmental safety, cost effectiveness and reliability.

In an oil heating system using a Tigerloop, all oil passes through the automatic oil deaerator, which effectively removes all gas/air bubbles from the system. This eliminates oil pump and nozzle problems associated with gas/air in the oil.

Tigerloop® Auto 2 Models: Smart Fuel Management

Two-Pipe Efficiency with One-Pipe Simplicity

Tigerloop® Auto 2 models combine the benefits of a two-pipe system for the fuel pump with the environmental and operational advantages of a one-pipe system for the fuel tank. Only the fuel consumed by the burner is drawn from the tank, reducing the transport of dirt particles and resulting in cleaner combustion.

Leak Prevention and System Safety

By eliminating the pressurized return line to the tank, the risk of leakage is removed, enhancing safety and reliability.

Self-De-Aerating Functionality

As fuel is drawn from the tank, air bubbles are released—especially when using Biodiesel, which has variable viscosity in cold conditions. These bubbles can cause disruptions, soot buildup, and wear on the pump or motor. Tigerloop® Auto 2 acts as a self-de-aerating day tank, eliminating these issues.

Built-In Fuel Heating

The friction generated by the pump heats the fuel circulating between the Tigerloop and the fuel pump, improving flow and combustion efficiency—especially beneficial in cold climates.

The Automatic de-aerator for diesel and liquid biodiesel. The Tigerloop® Auto 2 is designed to be compatible not only with diesel produced according to EN 590, but also biodiesel produced according to EN 14214 and HVO diesel (EN15940).

The Tigerloop Auto 2 models are also designed to meet new demands on energy savings, environmental and operational safety.

Features

Tigerloop Auto 2 is the perfect solution for de-aerating the fuel line before it reaches an auxiliary heater. When fuel is drawn from the fuel tank, or from a separate tank, air/gas bubbles are automatically released from the fuel. It is this air that causes problems for the fuel pump and ultimately for the heating system. The only way to ensure that the air does not travel to the heater is by de-aerating the fuel.

The Tigerloop Auto 2 automatically and continuously de-aerates the fuel by venting the air to atmosphere. This proven method of de-aeration ensures the best possible operating conditions for the fuel pump. By providing air-free fuel continuously to the heater, the Tigerloop Auto 2 ensures trouble-free performance at the highest possible level of efficiency. To be combined with a separate oil filter.

Environmental regulations and changes in fuel qualities continue to place high demands not only on material selection, but also on clean and air-free fuel for optimal combustion with minimal harmful emissions. Building on the innovation presented by Tigerholm in 1971, Tigerloop® Auto 2 models makes it possible to use a one-pipe system in all types of heating installations, thus ensuring the most environmentally safe method for transporting fuel from the fuel tank to the heater or motor.

Technical Data

| Model | Pump connections | Tank connection |

| TA110I | 1/4" female thread | 1/4" female thread |

| Technical data – Tigerloop® Auto 2 | |

| Suitable fuels | Diesel (EN 590) HVO diesel (EN15940) Biodiesel (EN 14214) |

| Max nozzle capacity | 110 l/h (29 GPH) |

| Max return oil pumped into the Tigerloop® | 120 l/h (32 GPH) |

| Max oil flow (consumption + return) | 230 l/h (61 GPH) |

| Max de-aerating capacity | 8 l/h (2 GPH) |

| Max operating temperature | 85°C (185°F) |

| Max. / Min. operating pressure in feed line | -0,6 / 0 bar ( -8.7 / 0 psi) |

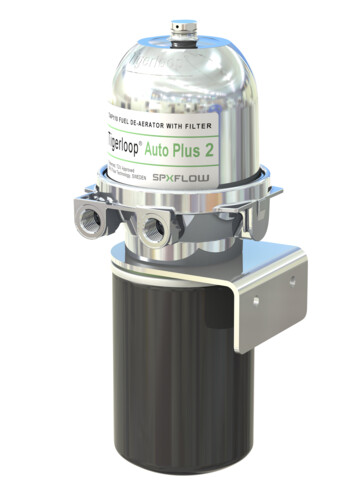

The Automatic de-aerator for diesel and liquid biodiesel, including a spin-on paper filter. The Tigerloop® Auto Plus 2 is designed to be compatible not only with diesel produced according to EN 590, but also biodiesel produced according to EN 14214 and HVO diesel (EN15940).

The Tigerloop Auto Plus 2 models are also designed to meet new demands on energy savings, environmental and operational safety.

Features

Tigerloop Auto Plus 2 is the perfect solution for de-aerating the fuel line before it reaches an auxiliary heater. When fuel is drawn from the fuel tank, or from a separate tank, air/gas bubbles are automatically released from the fuel. It is this air that causes problems for the fuel pump and ultimately for the heating system. The only way to ensure that the air does not travel to the heater is by de-aerating the fuel.

The Tigerloop Auto Plus 2 automatically and continuously de-aerates the fuel by venting the air to atmosphere. This proven method of de-aeration ensures the best possible operating conditions for the fuel pump. By providing air-free fuel continuously to the heater, the Tigerloop Auto 2 ensures trouble-free performance at the highest possible level of efficiency. To be combined with a separate oil filter.

Environmental regulations and changes in fuel qualities continue to place high demands not only on material selection, but also on clean and air-free fuel for optimal combustion with minimal harmful emissions. Building on the innovation presented by Tigerholm in 1971, Tigerloop® Auto 2 models makes it possible to use a one-pipe system in all types of heating installations, thus ensuring the most environmentally safe method for transporting fuel from the fuel tank to the heater or motor.

Technical Data

| Model | Pump connections | Tank connection |

| TAP110I | 1/4" female thread | 1/4" female thread |

| Technical data – Tigerloop® Auto Plus 2 | |

| Suitable fuels | Diesel (EN 590) HVO diesel (EN15940) Biodiesel (EN 14214) |

| Max nozzle capacity | 110 l/h (29 GPH) |

| Max return oil pumped into the Tigerloop® | 120 l/h (32 GPH) |

| Max oil flow (consumption + return) | 230 l/h (61 GPH) |

| Max de-aerating capacity | 8 l/h (2 GPH) |

| Max operating temperature | 85°C (185°F) |

| Max. / Min. operating pressure in feed line | -0,6 / 0 bar ( -8.7 / 0 psi) |

| Fuel Filter | 22 micron |