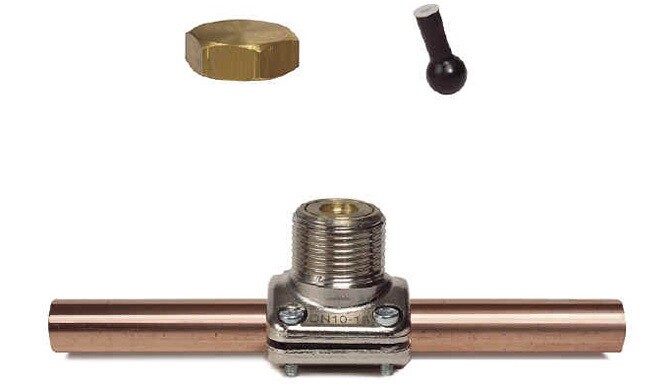

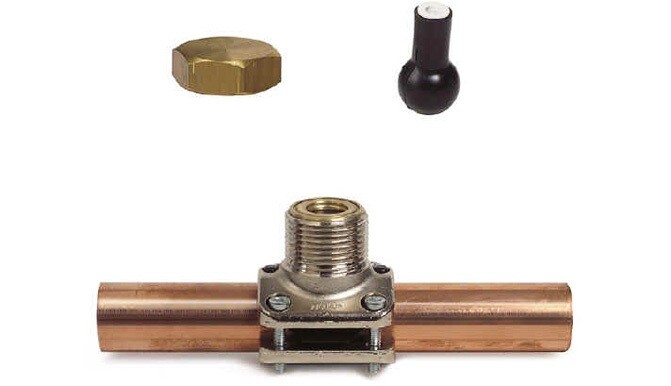

NoTap® pipe blocking is a complete system for easily and economically repairing pipes and installing or replacing equipment in your pipe system, without having to drain the system first. Sections of pipe to be worked on can quickly be temporarily isolated by means of internally blocking the pipes with inflated balloons.

The NoTap method can be used for hot water, fresh (tap) water, compressed air and refrigerants (glycol and salt based solutions). It is suitable for all pipes of metal, for example: black steel, painted steel, galvanized steel, stainless steal as well as copper. Valid for both thin-walled and annealed tempered pipe.

Blockings can be carried out on pipes up to DN50 (2") and connections up to DN300 (12").

10 Good Reasons to Use NoTap

- No need to drain the system

- No refilling or venting after work is completed

- Easy installation—no soldering, cutting, or welding required

- Compatible with all metal piping: black steel, painted steel, galvanized, stainless, and copper

- Saves energy—no hot water needs to be drained

- Suitable for hot water, fresh water, compressed air, and refrigerants (glycol and salt-based solutions)

- Eliminates risks associated with heating equipment like welding and soldering

- Less corrosion—no fresh, oxygen-rich water added

- Environmentally friendly—no hazardous water drained

- No drilling fragments enter the system

Advantages for the Contractor

- Significantly reduced job time

- Improved profitability—more jobs completed in less time

- Solves complex installation challenges

- Provides better service and solutions to customers

- No chemical handling required for cooling system modifications

Advantages for the Property Owner

- No disruption to tenants during pipe work

- Tradespeople can continue working (e.g., dentists, hospitals)

- Lower installation costs

- Work can be done during regular business hours—no need for costly after-hours labor

- Reduced corrosion increases system longevity

- Lower risk of water damage from open faucets

- Environmentally friendly solution

With NoTap you can carry out repairs and branch connections without first draining the system. You will save a lot of time and money and the method is simple!

Installing and replacing valves and pumps

Are you replacing a valve, pump or mixing valve in a system? Try our method of pipe blocking on each side of the valve or pump first. Then do your replacement with ease.

Repairing leaks

Do you have a pipe that is leaking? Try our method of blocking on each side of the leak. Then repair the leak quickly and easily.

Installing heat pumps, boilers and heat exchangers

Use NoTap when you need to rebuild the heating system. The installation will go quicker by using our method of blocking and you will avoid problems with corrosion as no fresh, oxygen-rich water is added to the system.

Heating equipment

With NoTap you will totally avoid problems associated with heating equipment such as welding, soldering, etc.