NoTap® is a complete system for easily and economically repairing pipes and installing branch connections on pressurized lines without first having to drain the system. The NoTap method can be used for hot water, fresh (tap) water, compressed air and refrigerants (glycol and salt based solutions). It is suitable for all pipes of metal, for example: black steel, painted steel, galvanized steel, stainless steal as well as copper. Valid for both thin-walled and annealed tempered pipe.

Branch connections on pressurized water or air pipe systems, sometimes referred to as hot taps, are done with ease using NoTap.

10 Good Reasons to Use NoTap

- No need to drain the system

- No refilling or venting the system after work is completed

- Easy installation—no soldering, cutting, or welding required

- Compatible with all types of metal piping: black steel, painted steel, galvanized, stainless, and copper

- Saves energy—no hot water needs to be drained

- Suitable for hot water, fresh water, compressed air, and refrigerants (glycol and salt-based solutions)

- Eliminates risks associated with heating equipment like welding and soldering

- Less corrosion—no fresh, oxygen-rich water added

- Environmentally friendly—no hazardous water needs to be drained

- No fragments from drilling operations enter the system

Advantages for the Contractor

- Significantly reduced job time

- Improved profitability—more jobs completed in less time

- Solves complex installation challenges

- Provides better service and solutions to customers

- No chemical handling required for cooling system modifications

Advantages for the Property Owner

- No disruption to tenants during pipe work

- Tradespeople can continue working (e.g., dentists, hospitals)

- Lower installation costs

- Work can be done during regular business hours—no need for costly weekend or after-hours labor

- Reduced corrosion increases system longevity

- Lower risk of water damage from open faucets

- Environmentally friendly solution

The clamp with a check valve is used for smaller branch connections (14-125 mm), installing an immersion pipe adapter and for blocking. For branch connections, a connector is mounted on the clamp that opens the check valve. For immersion pipes an adapter is mounted, and for blocking a balloon tool is used for inserting the balloon into the pipe.

Technical Data for Clamp with Check Valve

| Pipe dimensions: | OD 14 mm-125 mm (Cu 15-DN 100) |

| Branch connection (outlet diameter): | DN 20, (OD 14-23) mm or DN 25 (OD 24-125 mm) |

| Adapter for immersion pipe: | OD 24 mm-125 mm (DN 20-DN 100) |

| Pipe blocking: | OD 14 mm-60.3 mm (Cu 15-DN 50) |

| Flow diameter: | Ø 8.4 mm (OD 14-23 mm) or 14.4 mm (OD 26-125 mm) |

| Max. system pressure: | 16 bar / 10 bar (pipe dimension DN 65 and larger) |

| Max. temperature: | +95°C |

| Min. temperature: | –10°C |

| Type of pipes: | All pipes of metal, for example: black, painted, galvanized, stainless as well as copper. NB! NOT to be used for annealed copper pipe! |

| Media: | hot water, fresh (tap) water, compressed air and refrigerants (glycol and salt based solutions). For other applications, contact us. |

| Clamp material | Dezincification resistant brass |

| Seal | EPDM |

Dimension Guides

A variety of different types of branch connections are available. See the NoTap Guide for tables matching the correct dimension of pipe, drill size and clamp article numbers

Clamps with check valves are always used when pipe blocking (14-60,3 mm) and even for smaller branch connections. For branch connections, use one of our connectors which have a collar that opens the check valve.

For pipes with diameter 14 – 125 mm

- Straight or angled mini ball valve, Cu15 (G½")

- Optional valve with G½" or R¾" pipe thread

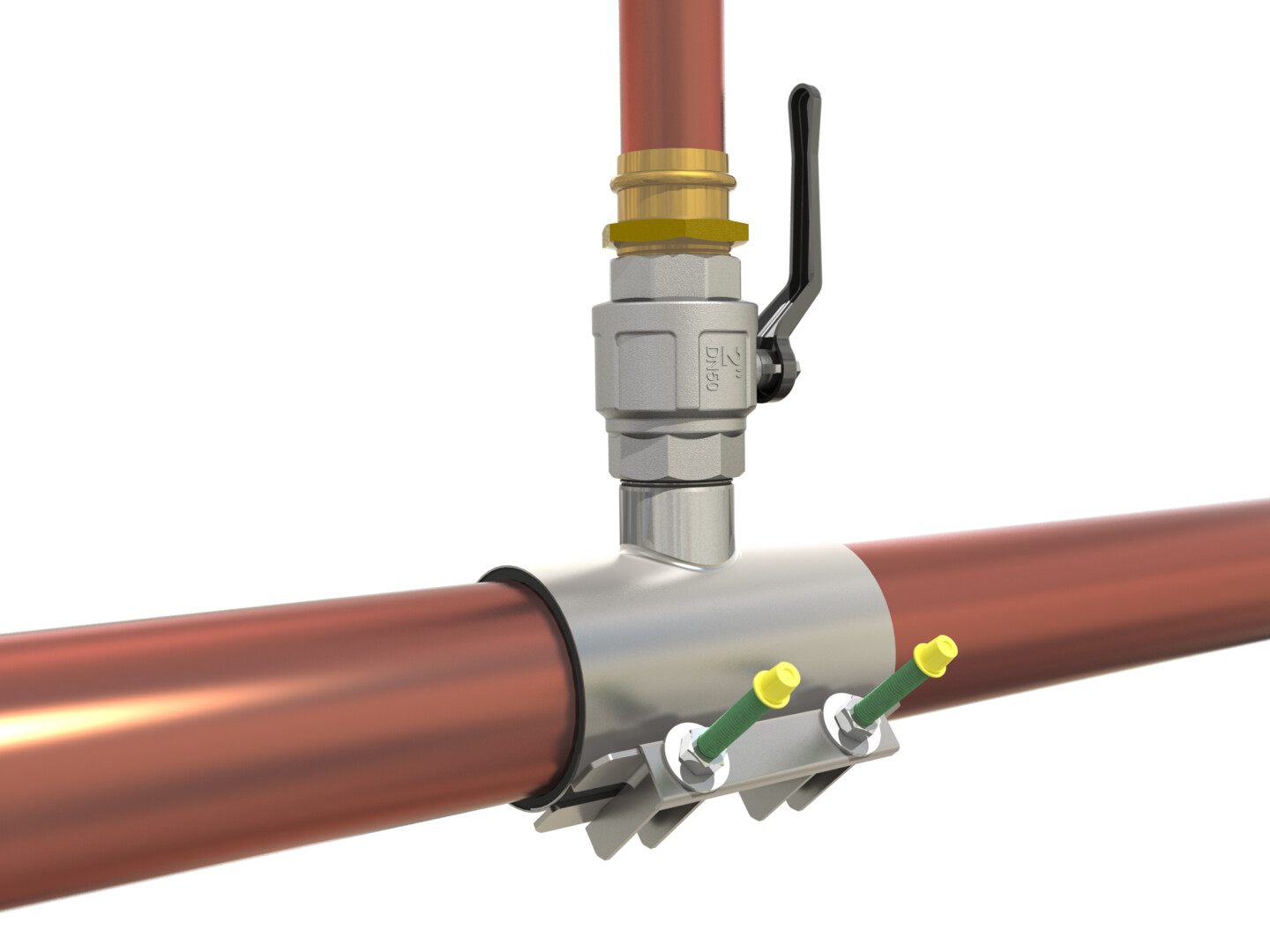

The clamp without a check valve is used when larger branch dimensions (26 - 335 mm) are desired for maximum flow from the branch connection. A full-flow ball valve shall always be fitted on these clamps when work is to be carried out on pressurized pipes.

Technical Data for Clamp without Check Valve

| Pipe dimensions: | OD 26-335 mm (DN 20-DN 300) |

| Branch connection (outlet diameter): | DN 25, DN 40, DN 50 or DN 65 |

| Flow diameter: | Ø 19-57 mm |

| Max. system pressure: | 16 bar / 10 bar (pipe dimension DN 150 and larger) |

| Max. temperature: | +95°C |

| Min. temperature: | –10°C |

| Type of pipes: | All pipes of metal, for example: black, painted, galvanized, stainless as well as copper. NB! NOT to be used for annealed copper pipe! |

| Media: | hot water, fresh (tap) water, compressed air and refrigerants (glycol and salt based solutions). For other applications, contact us. |

| Clamp material | Dezincification resistant brass / stainless steel (acid-resistant stainless steel for NoTap BIG, upon request) |

| Seal | EPDM (NBR on request) |

Dimension Guides

A variety of different types of branch connections are available. See the NoTap Guide for tables matching the correct dimension of pipe, drill size and clamp article numbers.

For pipes with diameter 26 – 170 mm

- Ball valve 1"

For pipes with diameter 54 – 165 mm

- Ball valve 1½", delivered with Ball valve with both low and high spindle

For pipes with diameter 70 – 134 mm

- Ball valve 2", delivered with Ball valve with both low and high spindle

For pipes with diameter 88 – 335 mm

- Ball valve 2½", delivered with Ball valve with both low and high spindle

Installation of new water outlet

You can make simple branch (T-pipe) connections in the kitchen or bathroom for installing, for example, a new washing machine, dishwasher, coffee maker or other household machines.

Installing new connections

NoTap allows you to easily connect additional piping to existing heating, water and cooling systems in the building. One example would be connecting a new radiator.

Installing gauges etc.

With the NoTap adapter for immersion pipes, a temperature gauge or other measuring device can easily be installed without draining the system.

Heating equipment

With NoTap you will totally avoid problems associated with heating equipment such as welding, soldering, etc.