Solids-Retaining Separators for Liquid/Solid Separation

SPX FLOW Seital Separation offers a wide range of solids-retaining separators for liquid/liquid/solid separation with very low solids content in the feed (less than 0.2% in volume). This type of separator allows efficient separation of a mixture into its two phases and the recovery of fine particles (0.5–500 µm) by means of a very high peripheral centrifugal field (G-force).

High-Speed Bowl Separation Process

The separation process takes place in the bowl of the high-speed separator, ensuring precise phase separation and particle recovery.

Theory of Operation

Separator Bowl

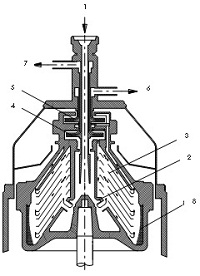

The product flows into the bowl through a feed pipe (1) and into the distributor (2) where it undergoes acceleration until it reaches the bowls rotating speed. The distributor (2) then conveys the product to the rising channels of the disks stack (3) where the separation between the heavy and light phases takes place. The high number of disks divides the internal space of the bowl into many thin layers, making the separation process more efficient. The light phase flows towards the center of the bowl and leaves the disk assembly via its inner edge. The heavy phase flows towards the bowls periphery. Both phases rise in the disk stack and reach the two upper chambers of the bowl where two fixed centripetal pumps (4-5) convey them under pressure to the outlet pipelines (6-7). The two pumps are surrounded by rotating liquid phases so, even if they are not rotating, they transfer the speed of the liquid into static pressure.

Solids removal

The solids impurities present in the product are collected in the periphery of the bowl (8) where they must be removed manually. If the solid phase is consistent, the solids sedimentation is relatively fast, so the machine must be periodically stopped for the removal. If solids are adhesive and very compact, Seital series separators may be equipped with a collection basket which permits faster removal of relatively dry solids. Valves and instrumentation that are necessary to control and regulate the separator (micrometric adjusting valves, manometers and sight glasses) are outfitted on inlet and outlet pipelines to ensure proper operation.