OVERVIEW

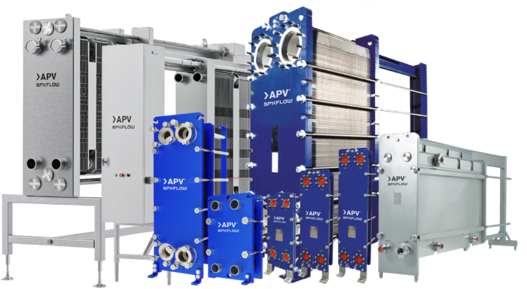

Our plate heat exchangers (PHEs) offer numerous benefits, including high heat transfer efficiency, versatility, easy maintenance, energy efficiency, cost-effectiveness, and safety, making them a popular choice for a wide range of industrial and sanitary applications.

Our solution makers invented the PHE more than a century ago and have continued to collaborate with customers to engineer innovative designs to meet their most challenging needs.

SPARE / REPLACEMENT PARTS

Why Select Genuine Spart Parts for Your Plate Heat Exchanger

Because Downtime is the Enemy of Efficiency

Certain plate heat exchanger replacement parts may seem attractive because of price, but saving on that initial cost could be a costly decision in the long run. There are reasons that alternative, “pirate” parts cost less, including the possible use of lower quality materials or not quite meeting design specifications. This could result in a part not lasting as long, lacking efficiency…or even damaging your equipment. SPX FLOW genuine spare parts are designed to exacting detail: material properties, specifications and dimensions are all measured meticulously. Differences in any of these product factors could have a significant effect on the efficiency, yield and health of your industrial machinery.

Why Use Genuine Spare Spares in Your Plate Heat Exchanger

Installing a third-party aftermarket plate in your PHE can lead to inefficiencies that can cost you money. The exact performance characteristics of a genuine APV heat exchanger plate are calculated for your specific application. Every feature of the plate selected by our experienced application engineers is designed to optimize performance. Third-party manufacturers may take shortcuts to minimize upfront expenses, which can hurt performance costing you in the long run. Additionally, a third-party aftermarket plate heat exchanger part into your original plate heat exchanger, will void your plate heat exchanger’s warranty. That’s because all our parts are engineered to our design specifications. Even the smallest of details are considered in the development of our genuine OEM spare parts to not just prevent damage to your equipment, but to also ensure your equipment continues to operate at the highest level of efficiency.

How to Get Genuine Spare / Replacement Plate Heat Exchanger Parts

Our global partner network means the plate heat exchanger replacement parts you need to stay up and running are readily available. And in the event you require expert installation, our partners are fully trained and ready to help at a moment’s notice.

Why Genuine Spare / Replacement Plate Heat Exchanger Parts Are Key

Safety is our top priority at SPX FLOW, which is why all our plate heat exchanger replacement parts endure rigorous testing and comply with regulatory requirements including 3-A and ASME standards. This commitment to safety translates to plate heat exchanger spare parts we stand behind. Can the same be said for third-party replacement parts?

No amount of downtime and certainly no potential safety hazard is worth saving a few bucks on a “might fit” part in the short term.

Don’t take unnecessary risk. Order genuine OEM plate heat exchanger replacement parts today, and rest assured you made the right decision.