FEATURES

Benefits:

- Over 30 year's operational experience specifically developing and utilizing swivel angle mixing technology

- Identical rugged, heavy duty design as for fixed angle mixers to extend service life

- Minimum maintenance requirements

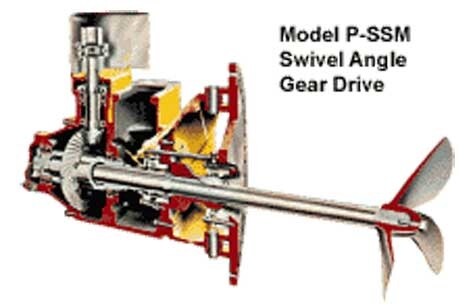

- Gear or belt drive options (see Models tab)

- Mechanical seal is standard supply

- Manufactured on modern computer controlled machining centers

- Optional automatic actuators available to negate need for manual swivel angle change

- CE & ATEX 2G certification available

Unique Tank Shut-Off Device All units incorporate a tank shut-off device to allow the shaft seal and bearings to be changed under full tank conditions. The tank shut-off mechanism incorporates tapered metal to metal faces, positively clamped by a bolted flange which both seals products in the tank and securely supports the shaft during bearing and/or shaft seal changes. All tapered faces are wear and corrosion resistant. The most important aspect of the Plenty Shut-off and mechanical seal assembly is that it incorporates a safety check valve for ensuring that the shut-off is 100% effective before removal of any bearings or the mechanical seal. The Plenty shut-off mechanism offers complete safety and security as it does not incorporate any flexible O rings or gaskets which may deform, wear, or perish.

Crude Oil, Bottom Sludge and Water (BS&W)

In most crude oils there are varying quantities of Bottom Sludge and Water (BS&W) which contains paraffins, heavy ends, sediments of sand / silts and water. The rate of accumulation varies with the quality of the crude stored.

Swivel Angle mixers incorporate a feature which allows the mixer angle of entry to be varied through 30° either side of the tank centerline in 10° increments and enables the entire tank floor to be directly scoured by the impeller flow stream. This is the only satisfactory solution to BS& W control in large tanks and ensures that the heavy solids, water and corrosive salts which settle in areas least agitated by a permanently fixed mixer are maintained in suspension.

Some of the main reasons why BS&W should be controlled are:

- Tankage is always available for storage and not out of commission being cleaned or repaired

- Problems of sludge disposal are overcome.

- Accumulation of BS&W can cause severe corrosion of tank floor and lower shell plates.

- Hazardous, dangerous and costly tank cleaning is practically eliminated.

- Large accumulations of BS&W can dramatically reduce ‘operations’ flexibility.

- If slugs of BS&W break free during pump-down then serious damage to the transfer pumps or even disruption of the refinery operation can result.

- Elimination of “plugged” water drains.

Combined Duties

It is possible that one or more of the duties may apply to a particular application and the most critical duty must determine the selection of mixer.

Swivel Mixers are capable of performing the same duties as a fixed angle mixer when fixed in the correct position.