NEWS RELEASE

SPX FLOW’s Scraped Surface Heat Exchanger Helps Reduce Energy Costs and Emissions

Margarine and shortening producers report a decrease in 30% of costs and 200 tons of carbon dioxide emissions annually per production line

Charlotte, N.C., October 27, 2022 - SPX FLOW, Inc., a leading provider of process solutions for the nutrition, health and industrial markets, reports that customers who use its latest scraped surface heat exchanger (SSHE), Nexus, in margarine and shortening production are better able to meet sustainability and business goals by reducing emissions and cost.

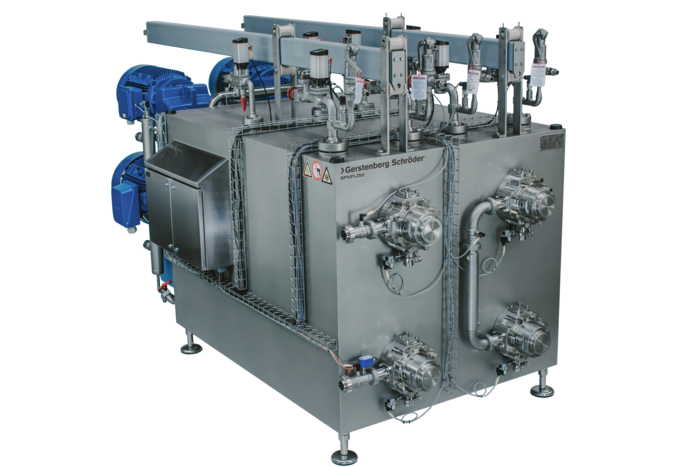

Nexus, the latest SSHE design made by SPX FLOW’s Gerstenberg Schröder brand, is a critical piece of equipment in forming the correct crystal structure in products like margarine, shortenings and other fats and oils products.

Nexus uses carbon dioxide (CO2) as a refrigerant rather than the traditional freon (HFC or HCFC) or ammonia (NH3).

“While most companies still use ammonia or freon, SPX FLOW has pushed for innovation by switching to carbon dioxide,” said Alf Sievers, Global Product Manager at SPX FLOW. “We pride ourselves on being solution makers, and our customers’ data proves how much Nexus makes a difference as we find the safest, most sustainable way to help our customers.”

Data shows that when customers began using the Nexus, each line improved its heat transfer by approximately 30% compared to other refrigerants. The data also confirms that the product quality improved compared to lines using other refrigerants.

Each line also reduces the annual CO2 emissions to the environment by about 200 tons annually when using CO2 compared to other refrigerants because of the higher efficiency. That’s roughly the same weight as 30 African elephants.

SPX FLOW recommends CO2 refrigerant because it’s safer and more sustainable than traditional refrigerants used in SSHE. Ammonia (NH3) is toxic — leaks can harm workers. And if freon leaks, it is harmful to the environment.

CO2 refrigerant is considered “cleaner” due to its Global Warming Potential (GWP) of one, according to the California Air Resources Board. Some types of freon, meanwhile, have a GWP potential of almost 4,000.

“Businesses are looking for more ways to be sustainable and meet climate goals, and results like this are an important step that helps do that,” said Sievers. “We will continue to work to innovate and create new ways to partner with our customers on this front.”

To learn more, visit: https://www.spxflow.com/gerstenberg-schroder/

About SPX FLOW, Inc.

Based in Charlotte, N.C., SPX FLOW, Inc. improves the world through innovative and sustainable solutions. The company's product offering is concentrated in process technologies that perform mixing, blending, fluid handling, separation, thermal heat transfer and other activities that are integral to processes performed across a wide variety of nutrition, health and industrial markets. SPX FLOW had approximately $1.5 billion in 2021 annual revenues and has operations in more than 30 countries and sales in more than 140 countries. To learn more about SPX FLOW, please visit www.spxflow.com.

Media Contact:

Melissa Buscher, Chief Communications and Marketing Officer

Melissa.Buscher@spxflow.com