NEWS RELEASE

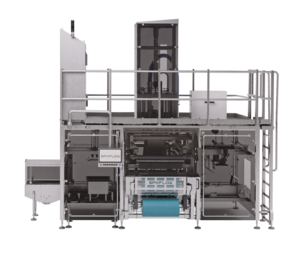

SPX FLOW Releases Safer, Easier to Operate Butter Bulk Packer

New design offers the latest innovations in hygiene, safety and ease of operations for semi-solid fat processors

Charlotte, N.C., Feb 21, 2023 - SPX FLOW, Inc., a leading provider of process solutions for the nutrition, health and industrial markets, has announced the new Gerstenberg Schröder Butter Bulk Packer BP5000 that prioritizes safety and ease of use.

Using the latest technology and innovation in the field, SPX FLOW’s experts built this bulk packer to meet all European standards, while being easier and safer to use.

“Safety is top of mind when it comes to the new technology used in this bulk packer, and SPX FLOW is proud of the innovations made,” said Erik Dons Soerensen, SPX FLOW’s Global Technical Sales & Market Manager for butter. “From a more hygienic product to the safety of the operator themselves, these improvements affect the operation from start to finish.”

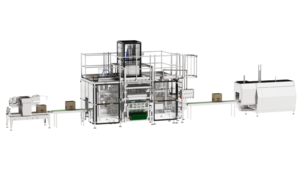

The fully-automated bulk packer separates semi-solid fat into individual product portions — from 10 kg (around 22 pounds) to 25 kg (approximately 55 pounds) cartons. While primarily used for butter, it can also be used for other types of crystalized fat, including vegetable fats and dairy blends.

Safety features include:

- A liner that closes before the carton leaves the machine, ensuring no exposure to free air outside the machine, which reduces the risk of airborne yeast and mold contamination

- Covered lining rolls

- An enclosed packaging machine

- An optional clean air filter that maintains cleaner air around the product filing area

- Transparent, noise-reducing safety doors to ensure safety and ease of use

- Integrated working platform for service

For operators, new technology allows for better operation and maintenance and, in turn, reduced downtime, including:

- Improved automation – with remote monitoring – including a fault diagnostic system for easy service and maintenance

- Operation featuring easily changeable liner rolls

- Flexible settings like easy changeover from 25 kg to 10 kg output

SPX FLOW team members’ expertise and years of experience provide both secure and reliable solutions, as well as knowledgeable customer service. This includes start-to-finish butter process line design, including automation and more.

“SPX FLOW prides itself on being ‘Solution Makers,’ and we’ll continue to work with customers to learn and grow with their needs,” said Soerensen. “Based on the feedback from our valued partners, we continue to innovate at every step to facilitate the best product and operation possible.”

For more information, visit Butter Bulk Packer type BP5000.

About SPX FLOW, Inc.

Based in Charlotte, N.C., SPX FLOW, Inc. improves the world through innovative and sustainable solutions. The company's product offering is concentrated in process technologies that perform mixing, blending, fluid handling, separation, thermal heat transfer and other activities that are integral to processes performed across a wide variety of nutrition, health, and industrial markets. SPX FLOW has operations in more than 25 countries and sales in more than 140 countries. To learn more about SPX FLOW, please visit www.spxflow.com.

Media Contact:

Melissa Buscher, Chief Communications and Marketing Officer

Melissa.Buscher@spxflow.com