NEWS RELEASE

APV Membrane Filtration Technology Takes Plant-Based Products to the Next Level

Expertise and resources help plant-based processors innovate and expand their offerings

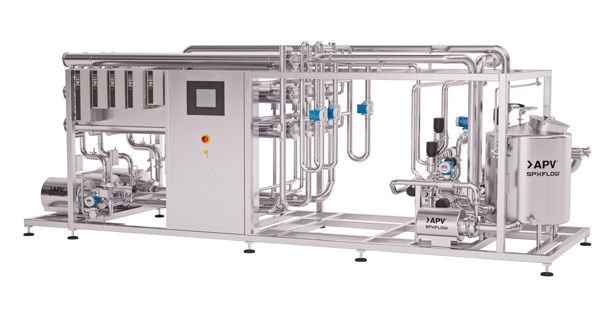

Charlotte, N.C., Feb 2, 2023 - SPX FLOW, Inc., a leading provider of process solutions for the industrial, nutrition and health markets, is introducing new technology for plant-based concentration using APV membrane filtration to provide clean label products of higher nutritional value. Benefits include a greater yield, higher single-source protein content and a more sustainable process compared to traditional methods using evaporation and chemicals.

The concentration of plant-based beverages can be used as a protein-enriched base for yogurt and cheese alternatives, food additives, and other nutritious ingredients, which results in higher single-source protein content.

The APV membrane filtration technology features a wide range of solutions designed to fit various plant sources, including soy, oat, nut, rice, pea and more. The solutions, designed based on processing needs, include process filtration like microfiltration and ultrafiltration for fractionation, concentration, and standardization of plant protein. Additionally, nanofiltration and reverse osmosis systems are available for solids concentration, valorization of subproduct, and water recovery.

“The benefits of this improved plant-based concentration are two-fold: a better, cleaner product for customers and a more sustainable, versatile and higher-yielding result for producers,” said Allan Vangsgaard, SPX FLOW’s Global Product Manager for Nutrition & Health, Membrane Filtration. “More than ever, customers are looking for a variety that includes plant-based products, and we are excited to work with our partners to help grow the options available.”

The traditional plant-based concentration involves chemicals or evaporation and can result in a significant loss of proteins. Our specialized membrane systems allow gentle separation and concentration of product proteins without damage and less than 1% loss. This process also means fewer filler ingredients to maintain the nutritional value of a plant-based product.

As more companies expand from dairy into plant-based options, SPX FLOW team members’ expertise and more than 60 years of experience provide both secure and reliable solutions, as well as knowledgeable customer service. This includes start-to-finish plant-based process line design, including mixing and blending, membrane filtration, homogenization, pasteurization, spray drying, valves and pumps, automation, and more.

SPX FLOW works with its partner companies to innovate both their products and the field of process solutions as a whole. With five Innovation Centers worldwide, including a membrane-specific Innovation Center in Silkeborg, Denmark, customers can test their products to find the best recipe or customized process.

Also, if a plant is already fitted for this type of concentration, producers can upgrade the membranes easily without overhauling the system.

“This filtration solution has been something our manufacturing partners have requested — and we listened,” said Vangsgaard. “This is a win-win for producers and manufacturers. We look forward to seeing the innovation that continues in the field.”

To learn more about SPX FLOW’s plant-based solutions, visit Plant-Based Processing.

About SPX FLOW, Inc.

Based in Charlotte, N.C., SPX FLOW, Inc. improves the world through innovative and sustainable solutions. The company's product offering is concentrated in process technologies that perform mixing, blending, fluid handling, separation, thermal heat transfer and other activities that are integral to processes performed across a wide variety of nutrition, health, and industrial markets. SPX FLOW has operations in more than 25 countries and sales in more than 140 countries. To learn more about SPX FLOW, please visit www.spxflow.com.

Media Contact:

Melissa Buscher, Chief Communications and Marketing Officer

Melissa.Buscher@spxflow.com