Overview

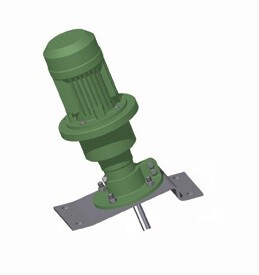

The Nettco i-Series mixer offers a lightweight, modular solution for global mixing applications. Designed for versatility and ease of use, this mixer can be configured for various mounting styles and process requirements, making it ideal for sanitary and industrial environments.

Modular Concept Features

- Lightweight aluminum construction

- Proven planetary gearing for robust performance

- Innovative modular design for quick configuration changes

- Reverse-taper shaft attachment enhances safety

- Motor range: 0.37 – 2.2 kW (½ – 3 HP)

- Washdown-rated (IP55), inverter-ready motor

- Optional air motor available

- Optional food-grade lubricant

- Fully standardized product for global compatibility

Performance & Speed Options

- Direct and gear drive options for full RPM range

- 50 Hz: 1450, 290, and 240 RPM

- 60 Hz: 1750, 350, and 280 RPM

- Shaft lengths up to 2100 mm (84")

Design & Impeller Options

- Simple, compact, and economical design

- Impellers from Lightnin’s industry-leading technology portfolio

- Available impeller styles:

- Hydrofoil

- PBT

- FP 100 (Marine Props)

Temperature Limits

- Ambient Temperature:

- Min: 32°F (0°C)

- Max: 104°F (40°C)

- In-Tank Temperature:

- Model P & Q: Max 200°F (93°C)

- Model L: Max 300°F (150°C)

- Model S: Max 250°F (121°C)