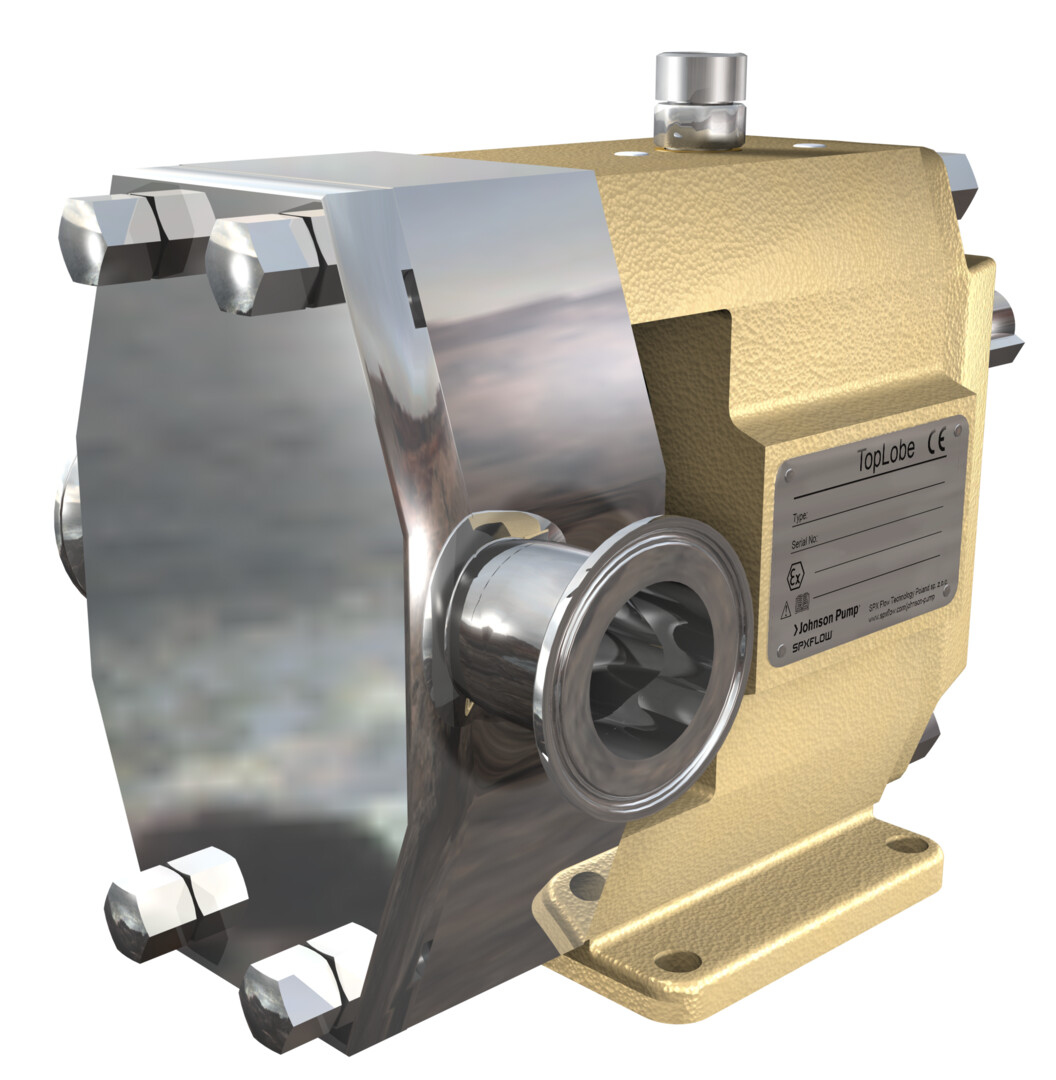

TopLobe - Rotary Lobe Pump

Tri-lobe rotary lobe pump, designed to handle most applications in today’s processing industries.

TopLobe Series Lobe Pumps

Overview

The TopLobe series is available in 12 different sizes. Shaft seal options include:

- Single mechanical seals

- Double mechanical seals

- Lip seals

Features include multi-foot mounting for vertical or horizontal installation, heating/cooling systems on the front cover, and optional built-on safety relief valves. Connection sizes range from 20 mm to 150 mm.

Benefits

- Simple, clean, robust construction: Hygienic design minimizes product entrapment, supports CIP/SIP/manual cleaning, and shortens cleaning downtimes

- Easy maintenance: Simplified gearbox construction allows for straightforward service

- Gentle product handling: Tri-lobe configuration offers low pulsation and safe transport of particle-laden fluids

- Large selection of shaft seals: Interchangeability ensures fast changeouts and minimal downtime

- Shim-free, oil-lubricated gearbox: Longer operational life and hassle-free servicing

- Certifications: ATEX Certified, CE Certified