Innovative Solutions for Agriculture and Aquaculture

We’re redefining the future of agriculture and aquaculture with cutting-edge solutions tailored to meet the industry's most pressing challenges. Our commitment to sustainability, efficiency and resource management is unwavering, ensuring our customers succeed in today's demanding environment.

Agriculture Solutions

Agriculture is essential to global food security, facing the dual challenges of water scarcity and the need for high productivity on limited arable land. SPX FLOW’s advanced fluid handling and mixing systems empower farmers to overcome these challenges:

-

Efficient Fluid Handling:

Our systems deliver precise irrigation and nutrient distribution, ensuring crops receive exactly what they need, minimizing waste and conserving water -

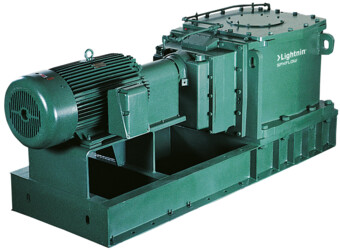

Advanced Mixing Technologies:

We provide innovative mixers that enhance the formulation of fertilizers and pesticides, which promotes soil health and supports sustainable plant growth. -

Greenhouse Climate Control:

With specialized pumping solutions, we optimize temperature and humidity within greenhouses, enabling consistent, year-round crop production regardless of external conditions.

Through these solutions, SPX FLOW is helping farmers achieve more with fewer resources, paving the way for a prosperous, sustainable agricultural future.

Aquaculture Solutions

As the global demand for seafood continues to rise, the aquaculture industry must balance increased production with the health of aquatic ecosystems.

-

Optimized Heat Transfer Systems:

SPX FLOW’s state-of-the-art heat transfer solutions play a crucial role in maintaining optimal water temperatures, essential for fish health and growth. -

Efficient Water Circulation and Aeration:

Our fluid handling systems facilitate efficient water circulation and aeration, vital for preserving water quality and reducing the environmental footprint of aquaculture operations. -

Sustainability in Seafood Production:

By integrating these advanced technologies, SPX FLOW helps aquaculture producers achieve higher efficiency and sustainability, contributing to responsible and sustainable seafood production.

Read our blog on the Benefits of Plate Heat Exchangers for Fish Farmers.

Proven Expertise and Client Success

Our commitment to innovation is reflected in the numerous testimonials from satisfied clients who have experienced the transformative impact of SPX FLOW's solutions. Farmers and aquaculture operators alike praise our ability to deliver customized, seamless solutions that not only meet but exceed their expectations. By integrating SPX FLOW technologies into existing systems, clients experience minimal disruption and maximum benefits, driving industry-wide advancements in sustainability and efficiency

Partnering for a Sustainable Future

At SPX FLOW, we are more than just a provider of technological solutions; we are dedicated partners in progress for the agriculture and aquaculture industries. Our focus on sustainability, efficiency and resource management equips our clients to confidently meet current challenges and future demands. By choosing SPX FLOW, industry leaders can embark on a journey toward a more sustainable and productive future.

Explore our innovative solutions and discover how SPX FLOW can help you achieve unparalleled success in agriculture and aquaculture. Together, we can cultivate a brighter, more sustainable tomorrow.

How Greenhouse Climate Control Works: Inside a Dutch Research Center Boiler Room

A plate heat exchanger works by transferring heat between two separate fluid streams without allowing them to mix. In the context of a fish farm, this technology is used primarily for heating or cooling water to maintain optimal temperatures for fish health and growth. Here’s how a plate heat exchanger functions in a fish farm: Design and Structure: A plate heat exchanger consists of multiple thin, corrugated metal plates arranged in a frame. The plates have grooves or ridges that aid in optimizing the heat transfer required. Flow of Fluids: There are two primary fluid streams involved in a plate heat exchanger setup: Hot/Cold Water Source: This is the fluid that carries heat to or from the fish tanks. It could be water from a boiler, heat pump, solar collector or other heating/cooling system. Fish Tank Water: This is the water circulating within the fish tanks, which needs to be heated or cooled as required. Operation: The hot or cold water source is directed into one set of alternate channels formed by the plates. The fish tank water is directed into the other set of alternate channels. As the fluids flow in opposite directions through their respective channels, heat is transferred between them through the thin plates. The corrugated design of the plates induces turbulence in the fluids, enhancing heat transfer efficiency. Heat is exchanged from the hotter fluid (e.g., hot water source) to the cooler fluid (e.g., fish tank water), thereby heating or cooling the fish tank water to the desired temperature. Efficiency: Plate heat exchangers are highly efficient due to their large surface area and turbulent flow characteristics. This design maximizes heat transfer between the two fluid streams while keeping pressure drops low. Temperature Control: By adjusting the flow rates of the hot/cold water source and the fish tank water, the temperature of the fish tank water can be precisely controlled. This is crucial for maintaining optimal conditions for fish growth, especially in aquaculture systems where water temperature plays a critical role. Advantages: Compact and space-efficient design. Faster heat transfer rates compared to alternative heat exchanger designs. Reduced energy consumption due to efficient heat transfer. Flexibility to integrate with renewable energy sources for heating. In summary, a plate heat exchanger in a fish farm facilitates the transfer of heat between two fluid streams, allowing precise control over water temperatures within fish tanks. This technology helps create a stable and optimal environment for fish growth, promoting better health and productivity in aquaculture operations. To learn more, read our blog on the Benefits of Plate Heat Exchangers for Fish Farmers.

Using a plate heat exchanger in a fish farm offers several advantages that make it a practical and efficient choice for managing water temperatures. Here are the key advantages: Efficient Heat Transfer: Plate heat exchangers are highly efficient at transferring heat between two fluid streams due to their large surface area and turbulent flow design. This efficiency ensures effective heating or cooling of fish tank water with minimal energy loss. Precise Temperature Control: Plate heat exchangers allow for precise control over water temperatures in fish tanks. By adjusting the flow rates and temperatures of the hot/cold water source, fish tank water can be maintained at optimal temperatures for different species of fish, promoting healthy growth and reducing stress. Compact Design: Plate heat exchangers have a compact footprint compared to other types of heat exchangers, making them suitable for installations where space is limited. This is advantageous for fish farms that need efficient heating or cooling solutions without requiring excessive space. Flexible Installation: Plate heat exchangers can be easily integrated into existing fish farm setups. They can be installed in line with the water circulation system, allowing for seamless integration with heating or cooling systems such as boilers, heat pumps or renewable energy sources like solar thermal panels. Energy Efficiency: By transferring heat between different water streams, plate heat exchangers contribute to overall energy efficiency in fish farming operations. They help optimize energy use by utilizing heat from renewable sources or waste heat from other processes, thereby reducing operational costs. Low Maintenance: Plate heat exchangers are relatively low maintenance compared to other heat transfer devices. They are designed for easy cleaning and inspection, reducing downtime and ensuring continuous operation in fish farm environments. Cost-Effective: Plate heat exchangers offer good value for money in terms of initial investment and operational efficiency. They provide effective heat transfer performance while being competitively priced compared to alternative heat exchanger technologies. Versatility: Plate heat exchangers can be used for various applications within a fish farm, including heating water for fish tanks, pre-heating incoming water for fish processing or controlling water temperatures in recirculating aquaculture systems (RAS). Reduces Environmental Impact: By optimizing energy use and facilitating the integration of renewable energy sources, plate heat exchangers contribute to reducing the environmental impact of fish farming operations. They help promote sustainable practices by minimizing energy consumption and greenhouse gas emissions. In summary, the advantages of using a plate heat exchanger in a fish farm include efficient heat transfer, precise temperature control, compact design, energy efficiency, low maintenance requirements and overall cost-effectiveness. These benefits make plate heat exchangers a practical and beneficial choice for maintaining optimal water temperatures and enhancing productivity in aquaculture settings. To learn more, read our blog on the Benefits of Plate Heat Exchangers for Fish Farmers.

When selecting a plate heat exchanger for a fish farm, several important factors should be considered to ensure optimal performance and efficiency. These factors include: Heat Transfer Requirements: Determine the specific heating or cooling needs of the fish farm, including the desired temperature range and the amount of heat transfer required to maintain optimal water conditions for fish health and growth. Flow Rate and Capacity: Consider the flow rate of the fish tank water and the capacity of the plate heat exchanger to handle this flow rate effectively. The heat exchanger should be sized appropriately to ensure efficient heat transfer without causing flow restrictions or pressure drops. Temperature Control Precision: Evaluate the temperature control capabilities of the plate heat exchanger. Ensure it can achieve and maintain the desired water temperature accurately, especially for sensitive fish species that require precise temperature regulation. Material Compatibility: Choose a plate heat exchanger constructed from materials that are compatible with the water quality and environmental conditions in the fish farm. Corrosion-resistant materials such as stainless steel or titanium are often preferred to withstand exposure to freshwater or seawater. Installation Flexibility: Consider the installation requirements and available space within the fish farm. Plate heat exchangers should be easy to install and integrate into existing plumbing systems, allowing for efficient operation and maintenance. Energy Efficiency: Look for a plate heat exchanger that offers high heat transfer efficiency to minimize energy consumption. Efficient heat exchangers can help reduce operational costs and promote sustainable energy use in fish farming operations. Cleaning and Maintenance: Choose a plate heat exchanger designed for easy cleaning and maintenance. Look for features such as removable plates or access ports that facilitate cleaning and inspection to prevent fouling and maintain performance over time. Pressure Drop: Evaluate the pressure drop characteristics of the plate heat exchanger. It should be designed to minimize pressure losses while effectively transferring heat, ensuring smooth operation without excessive pumping energy. Environmental Impact: Consider the environmental impact of the plate heat exchanger, including its material composition and energy efficiency. Opt for models that promote sustainable practices and minimize carbon footprint. Budget and Cost Considerations: Assess the initial cost of the plate heat exchanger as well as the long-term operating costs, including maintenance and energy expenses. Choose a heat exchanger that provides good value for money and meets the specific needs of the fish farm operation. Supplier Reputation and Support: Select a reputable supplier or manufacturer with a track record of providing quality heat exchangers and reliable customer support. Consider factors such as warranty coverage, technical assistance and availability of spare parts. By carefully considering these factors when selecting a plate heat exchanger for a fish farm, you can ensure the chosen equipment meets the requirements of the aquaculture operation and contributes to efficient and sustainable fish farming practices. To learn more, read our blog on the Benefits of Plate Heat Exchangers for Fish Farmers.

Yes, a plate heat exchanger can contribute significantly to reducing energy costs in a fish farm through several mechanisms: Efficient Heat Transfer: Plate heat exchangers are designed to maximize heat transfer efficiency due to their large surface area and turbulent flow characteristics. This efficiency means less energy is required to heat or cool water to the desired temperature compared to other heat transfer methods. Utilization of Waste Heat: Plate heat exchangers can efficiently capture and utilize waste heat from various sources within the fish farm. For example, waste heat from equipment such as pumps, generators or other processes can be transferred to heat fish tank water, reducing the need for additional heating energy. Integration with Renewable Energy Sources: Plate heat exchangers can be integrated with renewable energy sources such as solar thermal collectors, biomass boilers or geothermal systems. They facilitate the transfer of heat from these renewable sources to the fish tanks, reducing reliance on conventional energy sources and lowering energy costs. Optimized Temperature Control: By precisely controlling water temperatures in fish tanks, plate heat exchangers help minimize energy wastage associated with maintaining excessive or fluctuating temperatures. This targeted temperature control ensures that energy is used efficiently to meet the specific needs of the fish species being cultivated. Reduced Operational Costs: The overall energy efficiency of plate heat exchangers translates into lower operational costs for fish farms. Reduced energy consumption means lower utility bills and improved cost-effectiveness of fish farming operations. System Design and Sizing: Properly sizing and integrating a plate heat exchanger into the fish farm system can optimize energy use. By matching the capacity of the heat exchanger to the heating/cooling requirements of the fish tanks, energy losses due to oversizing or undersizing can be minimized. Maintenance and Performance: Regular maintenance of plate heat exchangers, including cleaning to prevent fouling or scaling, helps maintain their efficiency over time. A well-maintained heat exchanger operates more efficiently, further contributing to energy savings. Overall, the use of a plate heat exchanger in a fish farm can play a crucial role in reducing energy costs and promoting sustainable practices. By harnessing heat efficiently from various sources and optimizing temperature control, plate heat exchangers contribute to the economic viability and environmental sustainability of aquaculture operations. To learn more, read our blog on the Benefits of Plate Heat Exchangers for Fish Farmers.

Installing and integrating a plate heat exchanger into an existing fish farm setup involves several steps to ensure efficient operation and seamless integration with the existing plumbing and heating/cooling systems. Here is a general guide on how this process can be carried out: Site Assessment and Planning: Evaluate the fish farm layout and identify suitable locations for installing the plate heat exchanger. Consider factors such as available space, proximity to fish tanks and accessibility for maintenance. Determine the optimal positioning of the heat exchanger within the water circulation system to facilitate efficient heat transfer and temperature control. Selecting the Right Heat Exchanger: Choose a plate heat exchanger that meets the specific heating/cooling requirements of the fish farm, considering factors such as flow rate, temperature range, material compatibility and energy efficiency. Ensure the heat exchanger is appropriately sized to handle the heat transfer needs of the fish farm without causing flow restrictions or pressure drops. Installation Preparation: Prepare the installation site by ensuring it is clean, level and adequately ventilated. Arrange for necessary tools and equipment required for installation, including piping, fittings, valves and mounting hardware. Connecting Piping and Plumbing: Install inlet and outlet piping connections to the plate heat exchanger. Connect the hot/cold water source and the fish tank water supply lines to the appropriate ports on the heat exchanger. Ensure all connections are secure and leak-proof to prevent water loss or system inefficiencies. Integration with Heating/Cooling Systems: If the plate heat exchanger is part of a heating or cooling system, integrate it with the associated equipment such as boilers, heat pumps or renewable energy sources (e.g., solar thermal collectors). Install control valves, temperature sensors and flow meters as needed to monitor and regulate the flow of water through the heat exchanger. Electrical and Control Setup: If the heat exchanger requires electrical connections (e.g., for pumps or control systems), ensure all electrical components are installed according to safety standards. Set up control mechanisms to manage temperature settings and optimize the operation of the heat exchanger based on the fish farm's requirements. Testing and Commissioning: Conduct thorough testing of the plate heat exchanger system to check for leaks, proper flow rates and temperature control. Calibrate control systems and make adjustments as necessary to ensure optimal performance and energy efficiency. Commission the heat exchanger into full operation once all installation and integration tasks have been completed successfully. Training and Documentation: Provide training to operational staff on how to operate and maintain the plate heat exchanger effectively. Keep detailed documentation of the installation process, including equipment specifications, maintenance procedures and warranty information. Regular Maintenance and Monitoring: Establish a schedule for routine maintenance and inspection of the plate heat exchanger to ensure ongoing performance and reliability. Monitor energy consumption and system efficiency to identify opportunities for further optimization and energy savings. By following these steps, a plate heat exchanger can be successfully installed and integrated into an existing fish farm setup, contributing to efficient temperature control and energy management within the aquaculture operation. To learn more, read our blog on the Benefits of Plate Heat Exchangers for Fish Farmers.

When selecting an industrial mixer for fertilizer production, consider the following factors: Material Characteristics: Evaluate properties of raw materials such as particle size, density and moisture content, which influence the mixer type and configuration. Mixing Requirements: Determine the desired mixing intensity, duration and batch size to select a mixer that can meet specific production needs effectively. Corrosion and Wear Resistance: Select a mixer built with corrosion-resistant materials to withstand exposure to fertilizers, which can be abrasive and corrosive over time. Energy Efficiency and Operational Costs: Evaluate the mixer’s energy consumption and maintenance needs to ensure long-term cost-effectiveness.

When selecting a plate heat exchanger for a fish farm, several important factors should be considered to ensure optimal performance and efficiency. These factors include: Heat Transfer Requirements: Determine the specific heating or cooling needs of the fish farm, including the desired temperature range and the amount of heat transfer required to maintain optimal water conditions for fish health and growth. Flow Rate and Capacity: Consider the flow rate of the fish tank water and the capacity of the plate heat exchanger to handle this flow rate effectively. The heat exchanger should be sized appropriately to ensure efficient heat transfer without causing flow restrictions or pressure drops. Temperature Control Precision: Evaluate the temperature control capabilities of the plate heat exchanger. Ensure it can achieve and maintain the desired water temperature accurately, especially for sensitive fish species that require precise temperature regulation. Material Compatibility: Choose a plate heat exchanger constructed from materials that are compatible with the water quality and environmental conditions in the fish farm. Corrosion-resistant materials such as stainless steel or titanium are often preferred to withstand exposure to freshwater or seawater. Installation Flexibility: Consider the installation requirements and available space within the fish farm. Plate heat exchangers should be easy to install and integrate into existing plumbing systems, allowing for efficient operation and maintenance. Energy Efficiency: Look for a plate heat exchanger that offers high heat transfer efficiency to minimize energy consumption. Efficient heat exchangers can help reduce operational costs and promote sustainable energy use in fish farming operations. Cleaning and Maintenance: Choose a plate heat exchanger designed for easy cleaning and maintenance. Look for features such as removable plates or access ports that facilitate cleaning and inspection to prevent fouling and maintain performance over time. Pressure Drop: Evaluate the pressure drop characteristics of the plate heat exchanger. It should be designed to minimize pressure losses while effectively transferring heat, ensuring smooth operation without excessive pumping energy. Environmental Impact: Consider the environmental impact of the plate heat exchanger, including its material composition and energy efficiency. Opt for models that promote sustainable practices and minimize carbon footprint. Budget and Cost Considerations: Assess the initial cost of the plate heat exchanger as well as the long-term operating costs, including maintenance and energy expenses. Choose a heat exchanger that provides good value for money and meets the specific needs of the fish farm operation. Supplier Reputation and Support: Select a reputable supplier or manufacturer with a track record of providing quality heat exchangers and reliable customer support. Consider factors such as warranty coverage, technical assistance and availability of spare parts. By carefully considering these factors when selecting a plate heat exchanger for a fish farm, you can ensure the chosen equipment meets the requirements of the aquaculture operation and contributes to efficient and sustainable fish farming practices. To learn more, read our blog on the Benefits of Plate Heat Exchangers for Fish Farmers.

Choosing the appropriate impeller design is essential for achieving efficient blending and uniform fertilizer consistency. Here’s a guide on available options and selection considerations: Impeller Options: Flat-Blade Impellers: Recommended for low-viscosity or powder fertilizers, these impellers generate gentle flow, suitable for mixing without particle degradation. Axial Flow Impellers: Useful for high-flow applications, axial impellers move material vertically, creating an efficient top-to-bottom mixing ideal for bulk blending of liquid fertilizers. Radial Flow Impellers: Effective for applications requiring intense shear, radial impellers facilitate quick mixing and dispersal, ideal for handling granulated or multi-phase fertilizers. Helical and Anchor Impellers: Suitable for high-viscosity materials, these impellers help scrape the vessel walls to prevent material buildup, ideal for handling sticky or thick fertilizer mixtures. Selection Criteria: Material Characteristics: Consider particle size, density and moisture content to choose the mixer and impeller type that will best handle these properties without clogging or wear. Desired Mixing Intensity: High-shear impellers are optimal for thorough blending of complex mixtures, while low-shear options are better for maintaining the integrity of fragile particles. Batch Size and Production Speed: For large-scale continuous production, horizontal mixers with axial impellers may be most efficient. Smaller, batch-focused production often benefits from paddle or ribbon mixers. Compatibility with Corrosive Materials: Select impeller and mixer materials that are resistant to corrosion to handle fertilizer components that may be abrasive or reactive over time.

Using the Johnson Pump CombiLine Centrifugal Pump in greenhouse climate control systems offers numerous advantages for maintaining optimal growing conditions: Consistent Temperature and Humidity Control: The CombiLine efficiently circulates heated water from boilers throughout the greenhouse, ensuring even temperature and humidity distribution, which supports stable, year-round plant growth. Energy Efficiency and Reliability: Known for high efficiency and low energy consumption, the CombiLine minimizes operational costs. Its durable design also reduces downtime and maintenance needs, making it ideal for central thermal systems and heat pumps—giving greenhouses flexible, energy-efficient climate control options. Customizable Capacity: With sizes and capacities suited to different greenhouse scales, the CombiLine can be tailored to fit specific flow rate and heating needs, making it effective for both small-scale and industrial greenhouse operations. In summary, the Johnson Pump CombiLine Centrifugal Pump supports sustainable, efficient climate control, helping greenhouse operations maximize productivity and reduce environmental impact.

In large-scale fish farms, aeration pumps are essential for maintaining water quality and ensuring the health of high-density fish populations. Here are the key advantages: Enhanced Oxygen Delivery: High-capacity aeration pumps ensure adequate oxygen levels in large volumes of water, essential for the well-being of densely stocked fish populations. Efficient Waste Management: By promoting aerobic bacterial activity, these pumps support faster waste breakdown, reducing harmful toxins in the water. Uniform Water Circulation: Large aeration systems maintain consistent oxygen and temperature levels across extensive tanks, reducing dead zones and minimizing fish stress. Energy Efficiency in High-Volume Operations: Designed for 24/7 operation, industrial-grade aeration pumps deliver reliable oxygenation with low energy consumption, vital for cost-effectiveness in large-scale farms. Customizable for Facility Needs: Large-scale aeration systems can be customized for varied farm layouts, from flow-through tanks to extensive pond systems, supporting flexibility in aquaculture production. In summary, aeration pumps enhance oxygenation, water quality, and environmental stability, which are crucial for sustainable, productive large-scale aquaculture.