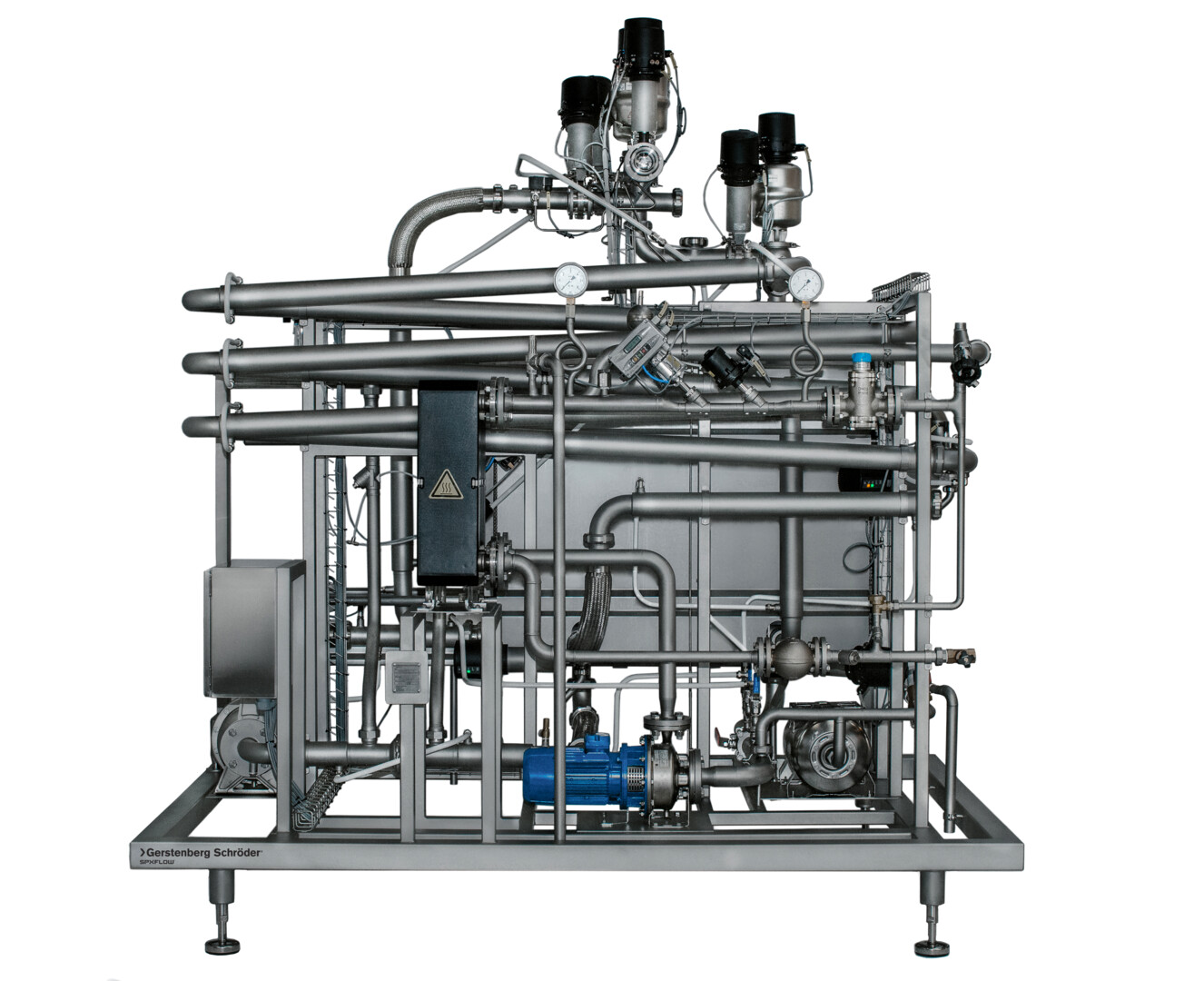

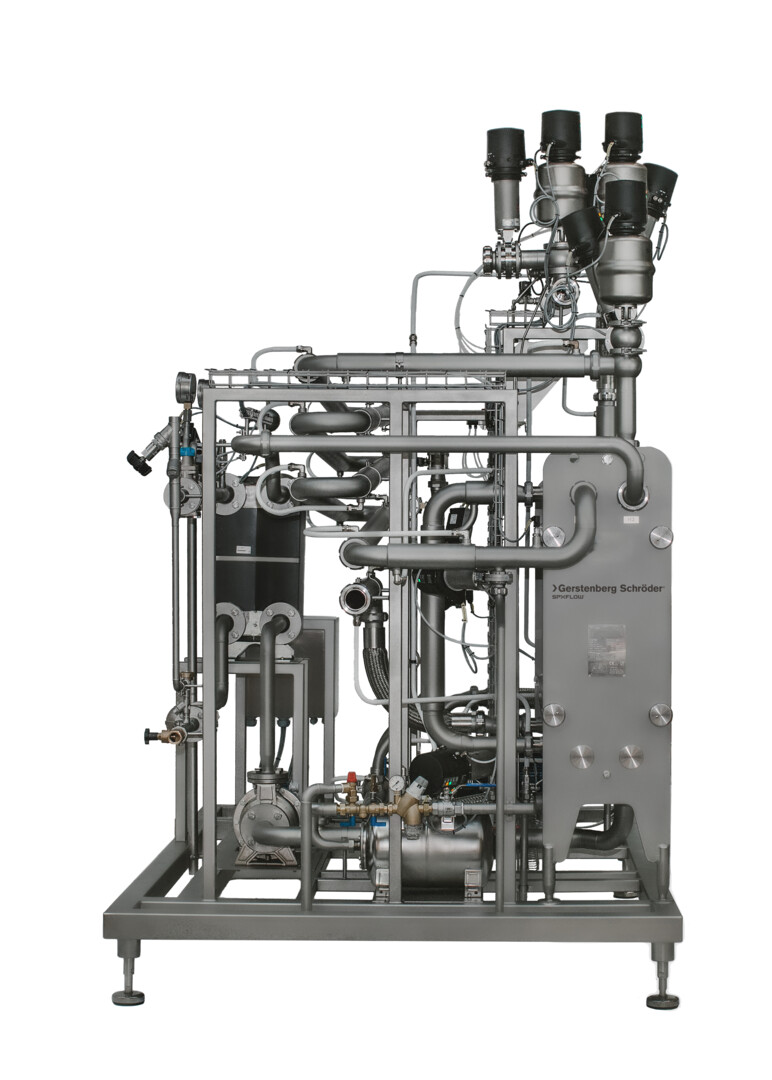

The Gerstenberg Schröder plate pasteurizer is designed for the thermal treatment of a variety of products within the Fats & Oils and Processed Food industries. It consists of a plate heat exchanger with three sections for heating, cooling, and heat recovery. It provides high performance, minimal downtime, and easy maintenance.

FEATURES

Function and Principles of Operation

The plate pasteurizer unit includes a soldered plate heat exchanger for making hot water by means of saturated steam, two water circulation pumps, temperature regulation valves and fittings. It is fully assembled, pre-wired and pre-hosed and ready to install.

The plate pasteurizer unit is robust, reliable and built to last in order to meet our customers’ wide-ranging product needs. Additionally, our solutions comply with the full spectrum of certification requirements.

Capacity

Up to 15,000 l/hour

Advantages

- Fast and easy maintenance securing maximum uptime

- Includes a heat recovery section which provides up to 70% energy savings

- For easy start-up (e.g. after a power failure), the plate pasteurizer unit is equipped with heated product pipes

- Completely pre-assembled, piped, pre-wired and ready to install