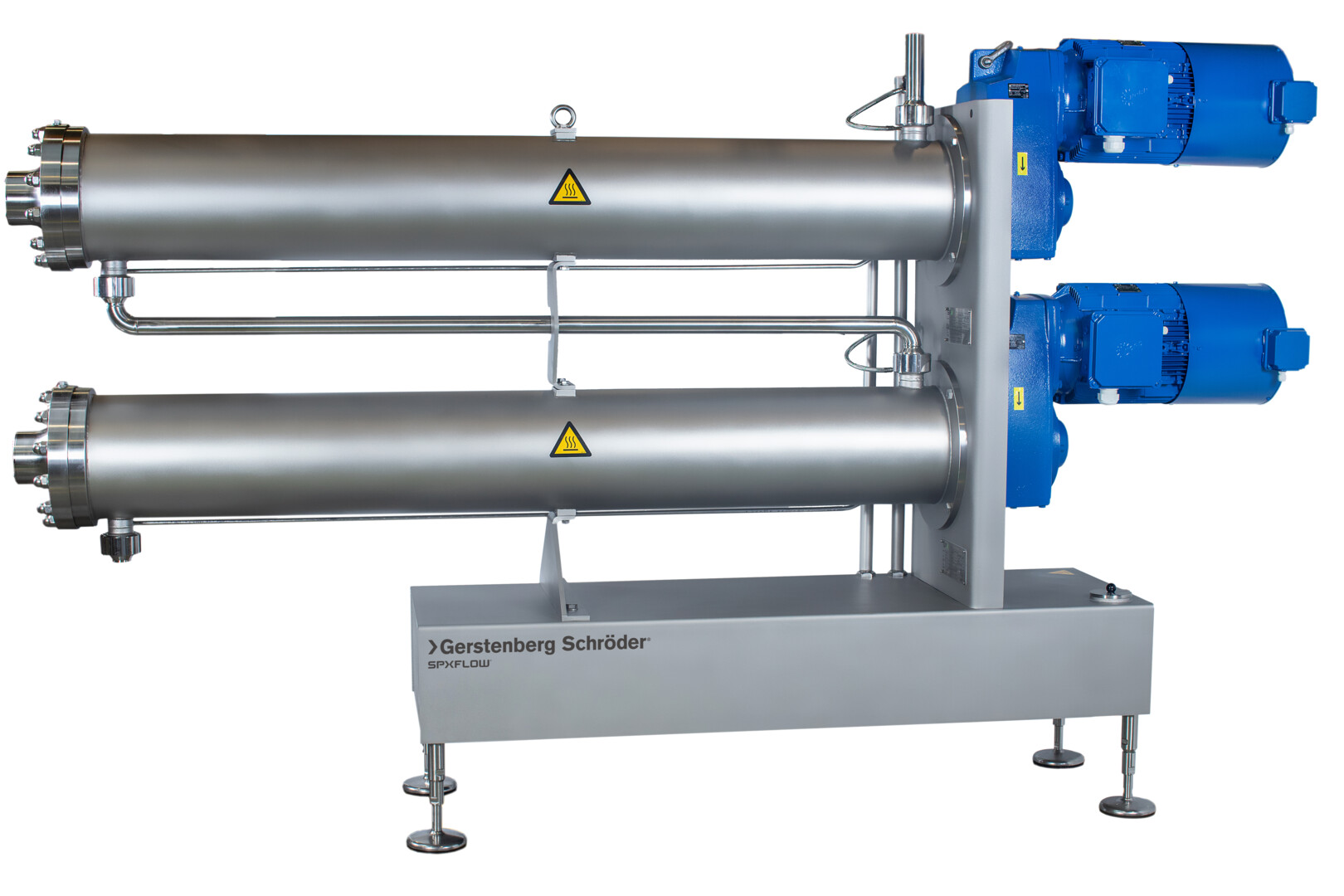

The Gerstenberg Schröder Pin Rotor Machine plays a key role in the manufacture of a wide range of margarine and shortening products by ensuring proper crystallization and consistency. Whether you need that extra degree of plasticity in puff pastry margarine, or the ideal viscosity for filling soft table margarine or shortening, our pin rotor machine moves you one step closer to perfection.

FEATURES

Function and Principle of Operation

Our Pin Rotor Machine offers flexibility in the production process in two, very important ways. Firstly, you can make adjustments to the level of intensity and the duration of kneading. This allows you to change the type of oil being used, in line with availability and market demand. This flexibility allows you to take advantage of oil price fluctuations without compromising product quality. Secondly, you have the flexibility to work with a wide variety of margarine and shortening products under high or lower pressure and variable speeds knowing that you can always depend on producing a high-quality, high-performing product.

The modular design enables you to mount up to three cylinders on a common base frame without occupying additional floor space. You can also mount the Pin Rotor Machine on top of the Nexus, Perfector and Kombinator. Furthermore, the Pin Rotor Machines are equipped with a built-in water unit.

Cylinder Volume

- 25 l.

- 50 l.

- 80 l.

- 100 l

- 200 l.

Advantages

- Flexibility

- Sanitary design meeting the highest standards of hygiene according to 3-A standards. All product contacting parts are made of AISI stainless steel and all product seals are in sanitary design

- Easy replacement of wearing parts during service and maintenance.

- Sliding parts are made of very long-wearing materials