The Gerstenberg Schröder Nexus Pilot Plant is a highly flexible and modular system designed to test various high-viscosity applications in the dairy, fats and oils, and processed food industries. It provides the opportunity to process small-scale samples under the exact same conditions as those in large-scale production facilities. The Nexus Pilot Plant is designed for high efficiency and low energy consumption, utilizing environmentally friendly and highly efficient CO2 as a refrigerant.

Nexus Pilot Plant: Modular Innovation for Thermal Processing

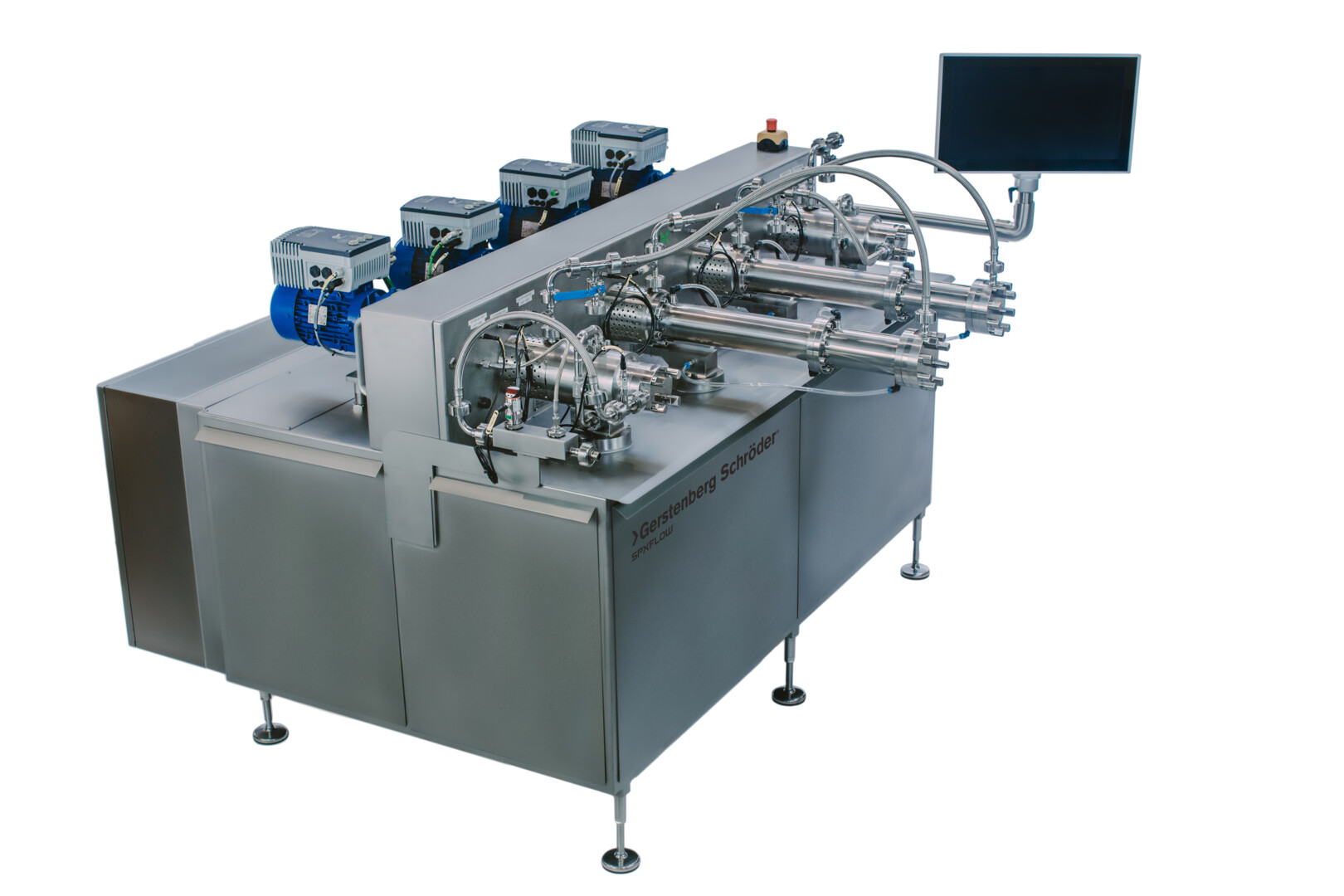

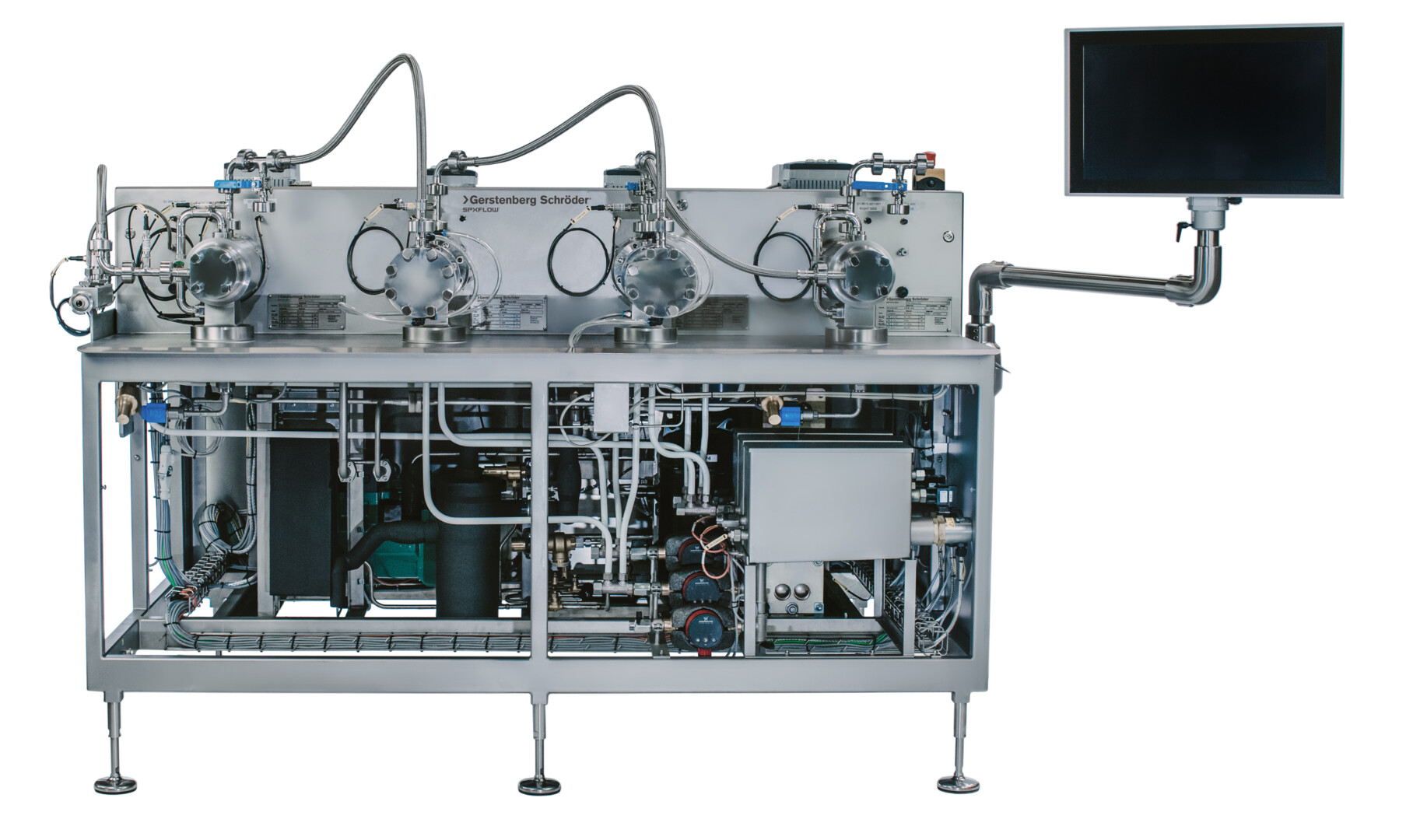

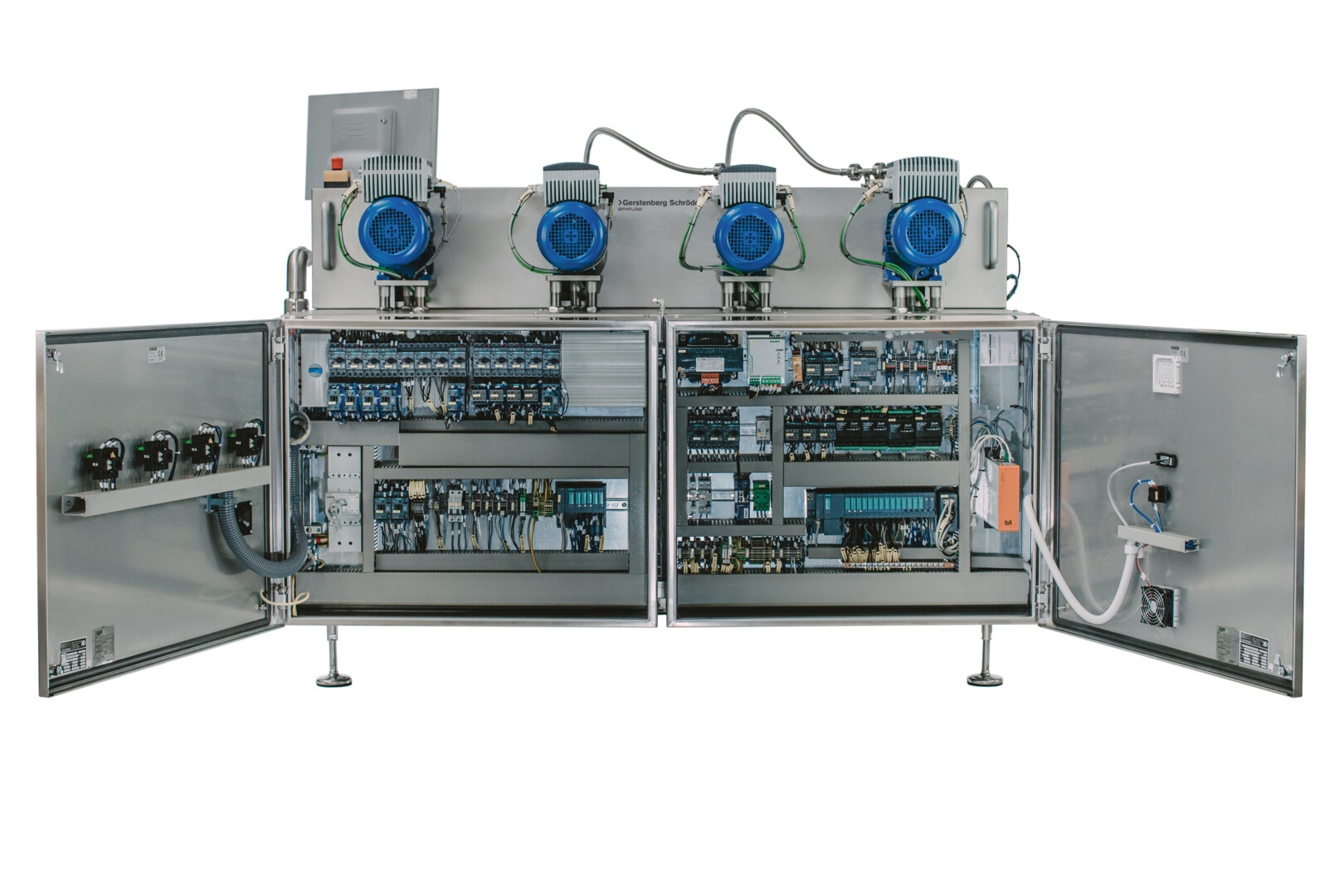

Skid-Mounted Modular Architecture

The system comprises multiple fully piped, wired, and factory-tested modules designed for flexible configuration and rapid deployment.

Core Table Module Design

Includes up to four slots for SSHE and pin rotor machines, CO₂ refrigeration, built-in compressor, and SCADA touch interface.

Additional Module Availability

Options include add-on tables for pin rotor machines, inverters, resting tubes, batching systems, pumps, pasteurizers, rework skids, and emulsifiers for processed food applications.

Quick Connection and Reconfiguration

Flexible piping enables fast reassembly for different applications with minimal disruption.

Function and Operating Principles

Crystallization via SSHE

Product cooling and crystallization occur inside the scraped surface heat exchanger, where centrifugal scraper force ensures efficient product consistency.

Production Capacity

Throughput Range

Capable of processing between 40–160 kg/hour.

Advantages of the Nexus Pilot Plant

Versatile Processing Capability

- Supports heating, cooling, crystallizing, and emulsifying for dairy, fats & oils, and processed foods

Scalable and Efficient

- Small-scale batch testing under real production conditions

- Plug-and-play setup with SCADA integration

Ease of Maintenance and Cleaning

- Quick set-up changes via flexible piping

- Streamlined cleaning and reduced downtime

Energy and Environmental Advantages

- Efficient CO₂ refrigeration delivers superior heat transfer and reduced energy use compared to ammonia and Freon

Dairy Industry

- Butter spreads

- Recombined butter

- Pastry butter

Fats & Oils Industry

- Bakery filling cream (fat-sugar creams)

- Cake and cream margarine

- In-house shortening

- Low fat spreads

- Margarine

- Puff pastry margarine

- Shortening

- Table margarine

Processed Food Industry

- Chocolate filling

- Chocolate spread

- Dressings

- Mayonnaise

- Milk rice

- Rice pudding

- Sauces