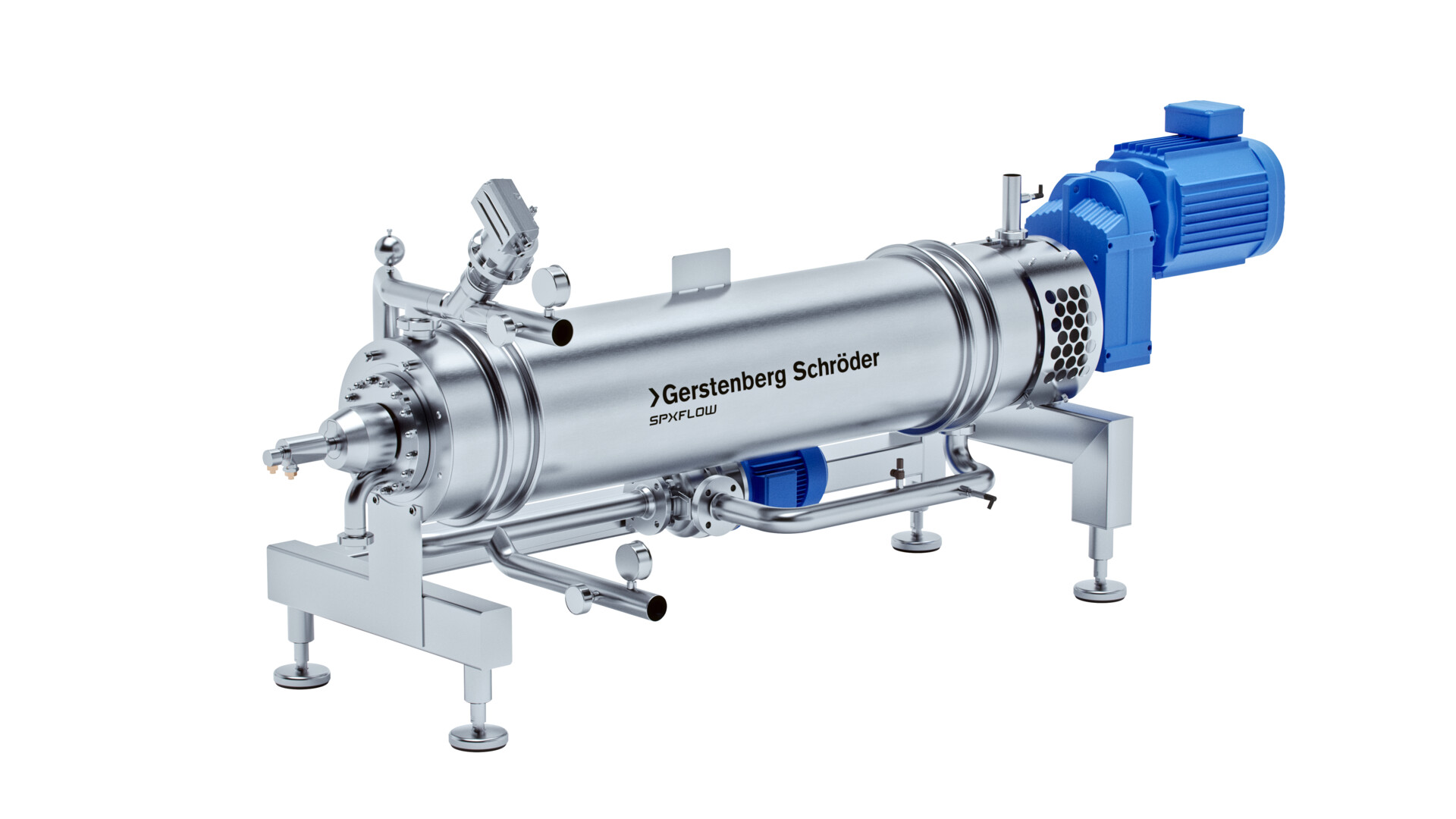

The Gerstenberg Schröder Consistator® MD is a low-pressure scraped surface heat exchanger designed to heat or cool medium to high viscosity products with or without particles within the Processed Food industry. It provides high performance, minimal downtime, and easy maintenance.

Consistator® MD: Versatile Thermal Processing Solution

Product Overview

Designed to meet market demands for high-quality, low-cost production across diverse food categories—from caramel and chocolate to sauces and mayonnaise.

System Architecture and Materials

Features a stainless steel, insulated multi-purpose jacket with customizable rotor sizes and media options (cooling water, brine, steam, etc.).

Modular Design

Flexible configuration allows up to 6 horizontally mounted units (excluding base frame), adaptable to modern food production needs and certifications.

Temperature Control

Integrated automatic regulation for independent temperature control across tubes enhances processing precision.

Function and Principles of Operation

Thermal Exchange Process

Product is pumped into a scraping tube system, enabling consistent mixing, scraping, and heat exchange via centrifugal rotor action.

Key Benefits

Multifunctionality and Hygiene

- Handles a wide range of consistencies and food types

- Contact surfaces built with hygienic AISI 316 stainless steel

Customization and Efficiency

- Modular system with rotor variations and vertical/horizontal layouts

- Corrugated chilling tubes and thin-walled cylinders for optimal heat transfer

Maintenance and Reliability

- Cartridge seals and blade materials for trouble-free operation

- Fast maintenance access and off-the-shelf replacement parts

Aseptic and Clean Design

- Flushable double mechanical seals suitable for aseptic and abrasive environments

- Clip-on insulation, short CIP/SIP cycles, and small footprint for operational ease

Scalability and Installation

- Expandable up to six modules for increased production capacity

- Quick delivery and easy installation