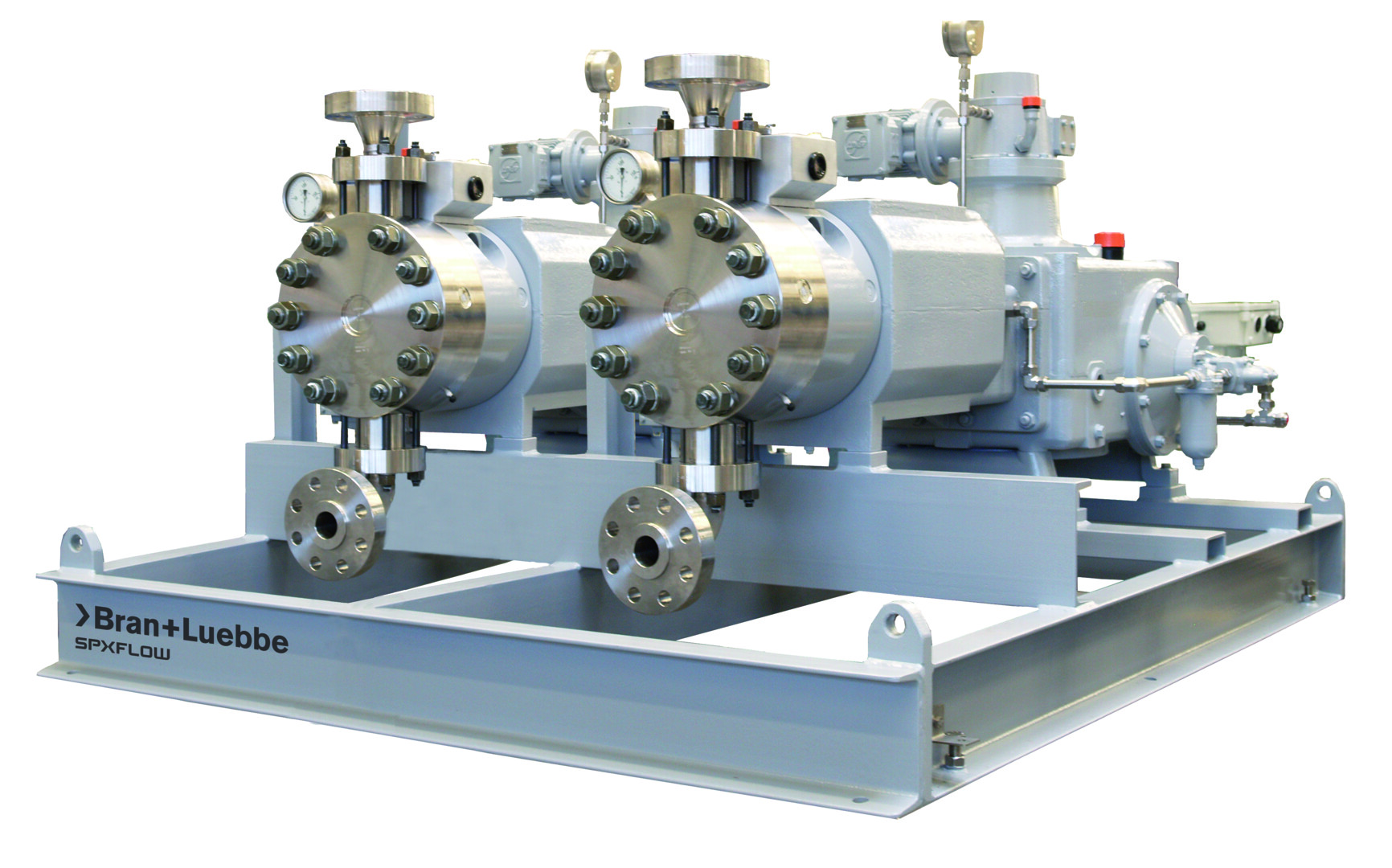

NOVADOS B Metering Pump

Nearly all gear sizes in the NOVADOS series can be combined for process and metering pumps to achieve the required flow rate and pressure parameters.

NOVADOS Pump Family Overview

Modular Design for Flow and Pressure Control

The NOVADOS Family includes both leak-free diaphragm and plunger pumps. Gear sizes in the series can be configured for optimal flow rate and pressure needs.

Materials of Construction

Liquid-Wetted Components

- Stainless Steel 1.4571 or 1.4462 housings

- PTFE or Stainless Steel 1.4310 diaphragms

- Stainless steel or ceramic plungers

- Optional materials: Super Duplex, Hastelloy, Titanium, and others

Pump Gear Design

Mechanical System

- Worm gear with multiple reduction ratios

- Splash lubrication

- Stroke length adjustment using eccentric Z-shaped crankshaft

Flow Rate Control Options

Manual and Automated Modes

- Manual, electric, pneumatic, or variable speed operation

Drive Technology

Electric and Custom Drive Options

- Electric motor with fixed or variable speed

- Custom drive configurations available upon request

Installation and Operating Conditions

Environmental Suitability

- Hazardous areas: up to Zone 1 IIC T4 (Zone 22 available upon request)

- Ambient temperature: −40°C to +50°C

- Fluid temperature: −40°C to +150°C

*These values are indicative. Please specify actual operating conditions when inquiring.

Performance Benefits

Flexible, Scalable, Efficient

- Hermetically sealed pump design

- Individually adjustable stroke lengths for fine-tuned control

- Variable speed drive maintains efficiency across conditions

- Automation enhances productivity

- Systems can be expanded with additional pumps or automated control