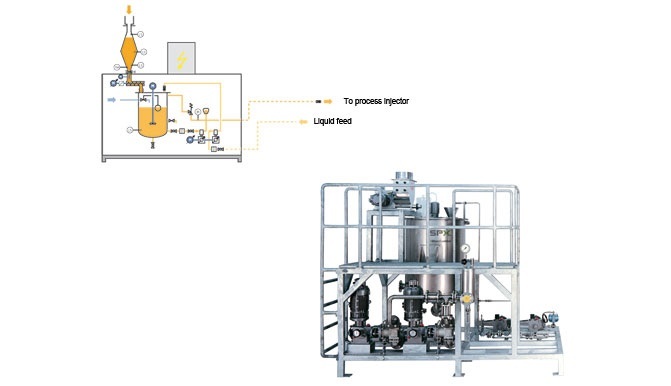

Continuous Production of Hydrosulfite Bleach in the Paper Industry

On-Demand Bleach Preparation Benefits

Producing hydrosulfite bleach solution as needed ensures short holding times, higher bleaching activity, and reduced chemical consumption. All metering, mixing, and control components are integrated into a compact space-saving system. This eliminates the need for separate mixing/storage vessels and avoids delays linked to batch production.

Automated Hydrosulfite Bleach Production Process

Powder Delivery System

Hydrosulfite powder is stored in a container and passes through a feed shaft into a screw feeder.

Dilution and Mixing

The screw feeder dispenses a measured amount of powder into a stirred dilution vessel. Simultaneously, water is added via a float valve for accurate dilution.

Proportional Component Control

Screw feeder and metering pumps (for sodium hydroxide and complexing agents) are automatically regulated based on pulp flow, using an inductive flow meter. This ensures correct solution ratios and quantities are maintained in real time.