Continuous Dilution of Alkyl Ether Sulphate Pastes: Efficient, Safe, and Scalable

Modern Requirements for Tensides

Surfactants must offer wetting, dispersing, cleansing, skin tolerance, and biodegradability—alkyl ether sulphates deliver all.

Product Forms and Traditional Challenges

Available as 28% liquid and 70% paste, alkyl ether sulphates faced dilution issues due to gel phase formation during processing.

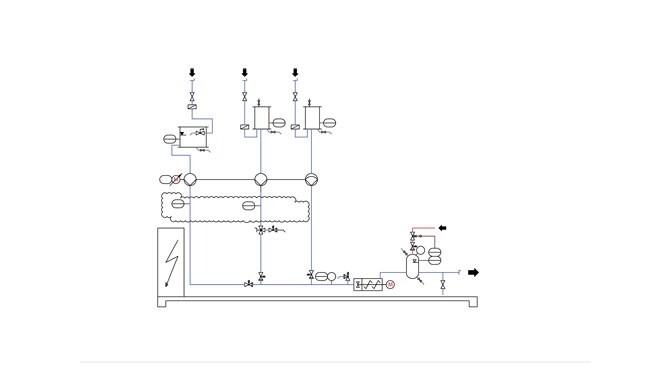

Bran+Luebbe’s Optimized Dilution Approach

Proprietary systems prevent gelatinous phase formation, using frequency-controlled mixers and strategic injection design.

Consistency and Performance

Multi-head pump synchronization ensures homogeneous product quality regardless of mechanical slip.

Material Characteristics

High-viscosity 70% paste is shear-thinning and pumpable; 28% liquid variant is low-viscosity and storage-friendly.

Process Efficiency and Thermal Independence

No preheating of water or paste required—even at 8°C ambient temperatures—cutting energy use and contamination risks.

Operational Benefits of On-Demand Dilution

- Reduced microbiological risk using sterilized water

- Compatible with stainless steel or fiberglass storage tanks

- Maintains processing temperature above +20°C

Advantages of Continuous Dilution Systems

- Cost-effective procurement and logistics with 70% WAS paste

- Expanded storage without additional tank investment

- Automated dilution with level-based controls

- Adaptable for batch or continuous cosmetic production

- Time and energy savings over conventional systems

- Minimized preservative usage