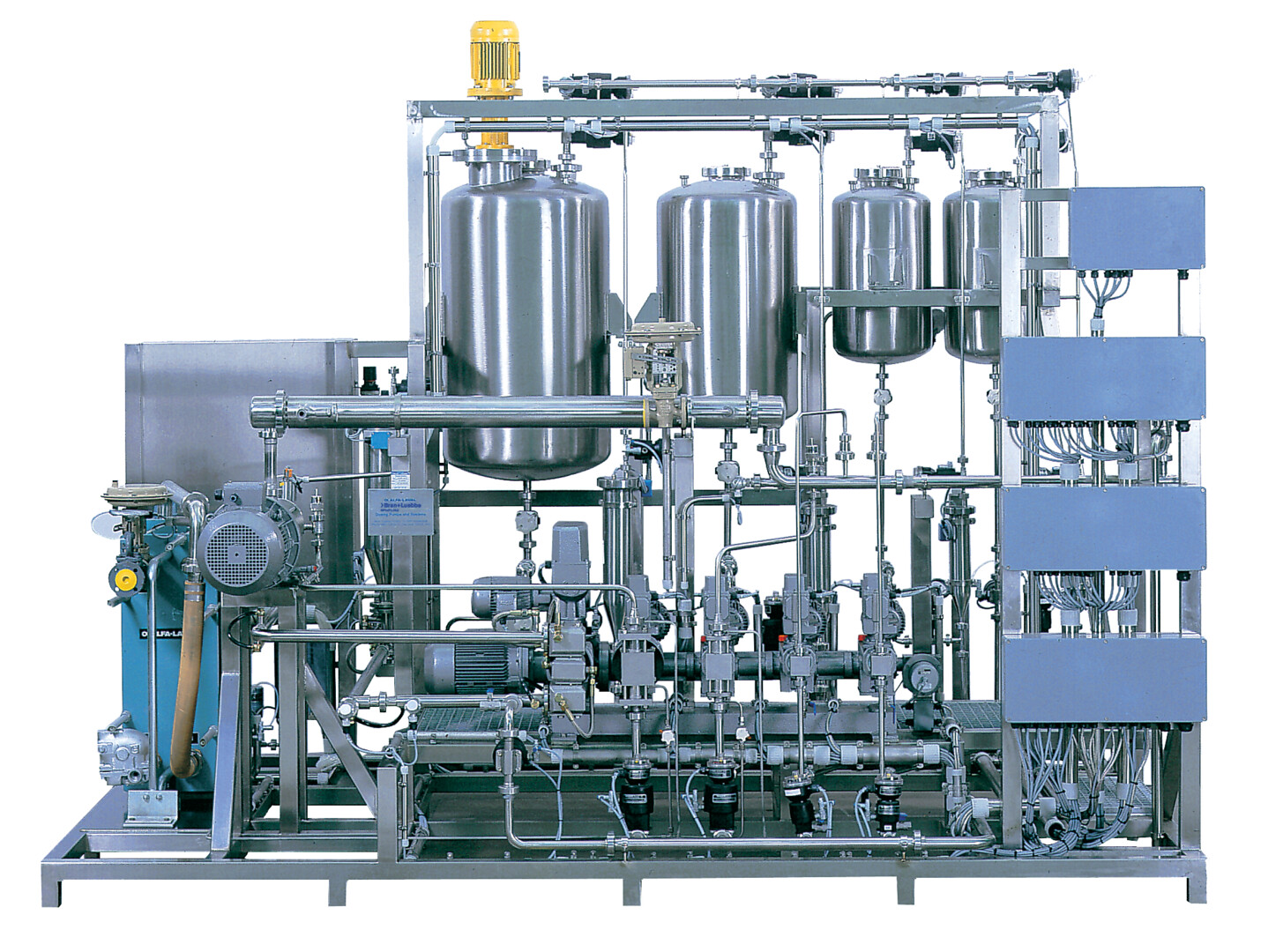

AutoBlend System - Body Lotion Production

Continuous production of high quality body lotion is achieved using a Bran+Luebbe metering and mixing system, incorporating emulsification with a Bran+Luebbe PENTAX mixer.

Continuous Production System for High-Quality Body Lotion

Integrated Metering and Mixing Solution

Utilizes Bran+Luebbe metering and mixing equipment, including a PENTAX emulsification mixer and tube heat exchanger for temperature control.

System Design Highlights

Computer-controlled setup features mass flow meters, LIV stream monitoring, and aseptic CIP-enabled architecture.

Operational Advantages

Performance and Quality

- Sterile, continuous production with direct filling line integration

- Eliminates air contamination in the final product

- Ensures consistent product quality throughout production

- Automatic cleaning and sterilization via CIP system

Core System Components

Equipment Overview

- 1 Type KH metering pump with electric delivery control and plunger head

- 4 Type P metering pumps with electric control and 4 plunger heads (1 heated)

- 1 PENTAX dynamic mixer

- 3 sanitary pipe heat exchangers

- 1 on-line mass flowmeter

- 1 on-line pH analyzer

- 1 on-line viscosity analyzer

- Automatic valves for flow regulation

Automation and Process Control

Smart Features

- Fully automatic control system

- Recipe handling with integrated reporting

- Real-time monitoring with feedback loops

- Automatic shutoff for ingredient depletion