BacktoMain

Products

- Analyzers

- Automation Systems

- Butter Equipment

- Centrifuges

- Cleaning-in-Place Systems

- Controlled Bolting

- Deareators

- Draught Regulators

- Dryers

- Evaporators

- Fat Crystalization Equipment

- Filters & Strainers

- Heat Exchangers

- Homogenizers

- Membrane Filtration Systems

- Microparticulation Systems

- Mixers & Agitators

- Pigging Systems

- Plumbing Products

- Pumps

- Recreational Marine Products

- Spin Flash Dryers

- Spray Dryers

- UHT Systems

- Valves

- Adhesives & Sealants

- Automotive Heating System

- Baby Food

- Bakery Filing Cream

- Beer, Cider, Wine & Spirits

- Boats & Watercraft

- Building Infrastructure

- Butter & Spreads

- Cement

- Cheese

- Chocolate

- Coffee & Tea

- Condiments, Sauces & Soups

- Cosmetics

- Dairy Powders

- Flavors & Fragrances

- Fruit Juice

- Fuel Supply System

- Hair, Nail & Skin Care Products

- Ice Cream

- Inorganic Chemicals

- Margarine & Shortening

- Meat & Animal-Based Proteins

- Milk & Cream

- Neutralization

- Nutraceuticals

- Oral Care

- Paints & Coatings

- Petrochemicals

- Pipelines

- Plant-Based Food & Beverages

- Plastic & Resins

- Refinery

- Soft Drinks

- Solvents & Solutions

- Specialty Chemicals

- Synthetic Rubber

- Yogurt

- Aerospace

- Chemical

- Dairy

- Fats & Oils

- Food & Beverage

- Oil and Gas

- Personal Care

- Pharmaceutical

- Water and Wastewater Treatment

- Horticulture

- Agriculture / Aquaculture

- Automotive

- Construction

- Defense & Military

- Electric Vehicle

- HVAC

- Mining

- Plumbing

- Power & Energy

- Pulp & Paper

- Rail

- Recreational Marine

- Shipbuilding

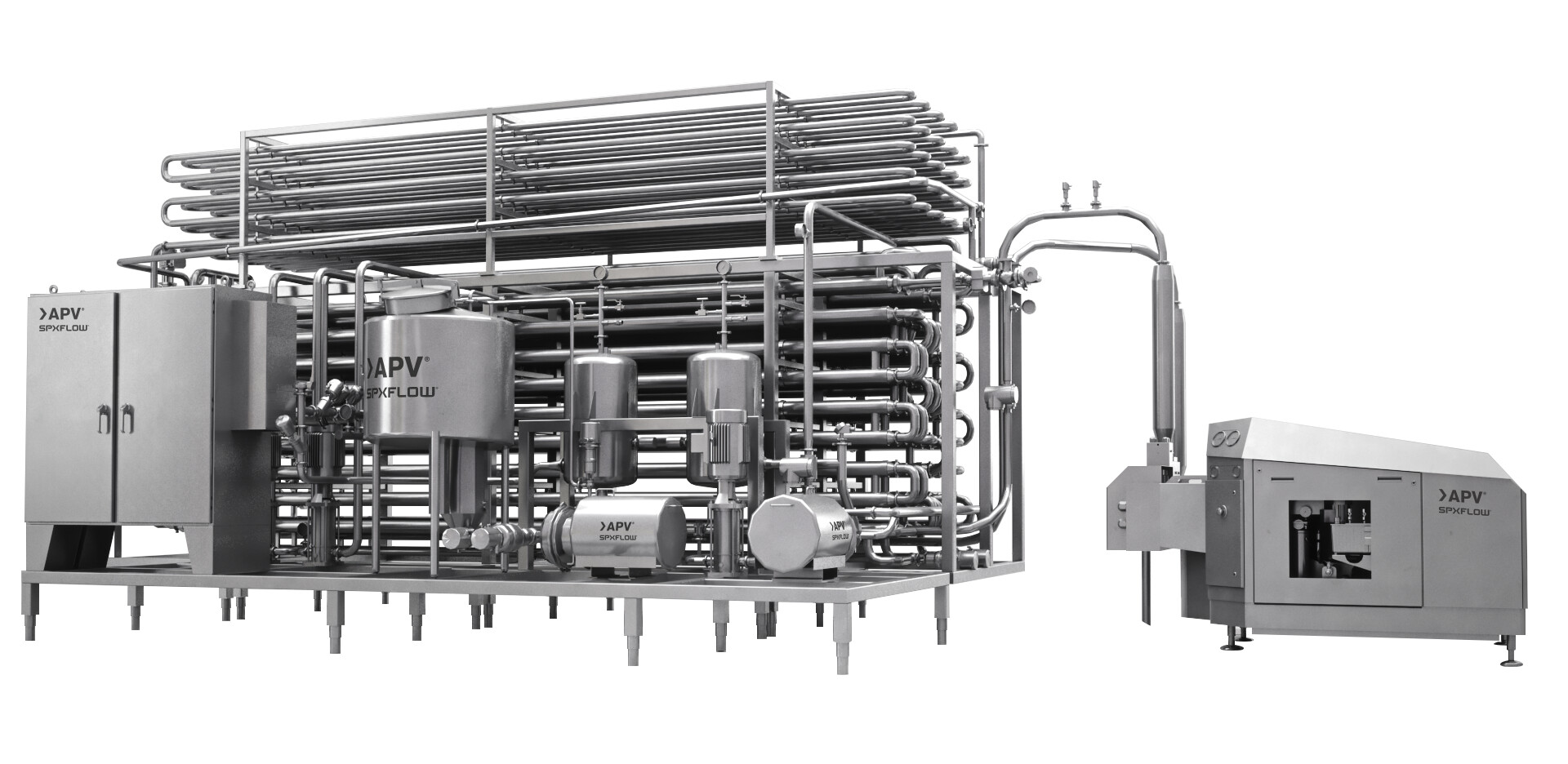

Tubular UHT System

Product Type(s) : Tubular UHT Systems

Description :

REQUEST PRICING

Tubular UHT Express Systems designed for use with standard UHT food, dairy, beverage, and a variety of specialty products up to 19% total solid. Standard systems designed for easy ordering, fast delivery, low cost and, based on our vast experience, without compromise on performance.

FEATURES

Designed to optimize output

- High turbulence decreases fouling and shortens cleaning time

- High product flow velocity minimizes fouling and extends run time between CIP

- Easy inspection and access for shorter maintenance times

Food safety

- High bacteria kill rates

- Sharp separation of product and process water

- Efficient, effective cleaning

- Lower energy consumption

Other key features

- Extended energy recovery

- Pre-assembled and factory-tested for easy and fast installation

- Capacities: 6,600; 13,000 , 20,000 and 26,000 ltr/hr

- CIP and PLC systems included

- Customized SPX FLOW service and maintenance agreements

- Global delivery of genuine spare parts and aftermarket support

- Application testing at the SPX FLOW innovation centers in Denmark and China