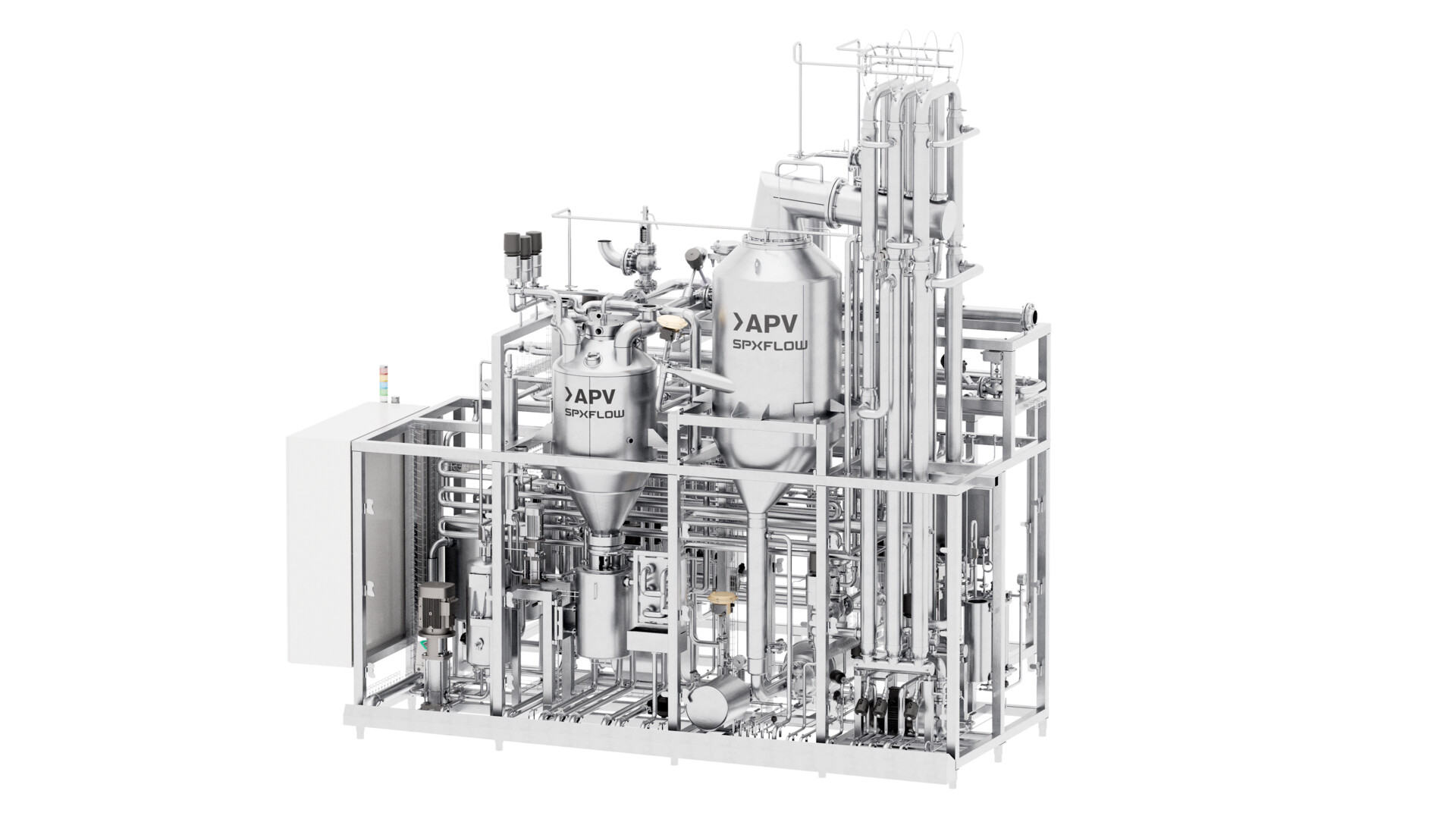

Seamless Infusion Vessel for UHT Processing

The APV® Seamless Infusion Vessel is a groundbreaking addition to our APV UHT processing systems, revolutionizing dairy, plant-based and beverage production. APV Seamless Infusion Vessel minimizes fouling challenges in Infusion UHT systems, ensuring extended run times, and maximizing operational efficiency. Moreover, its sustainability focus reduces resource consumption and overall operating costs.