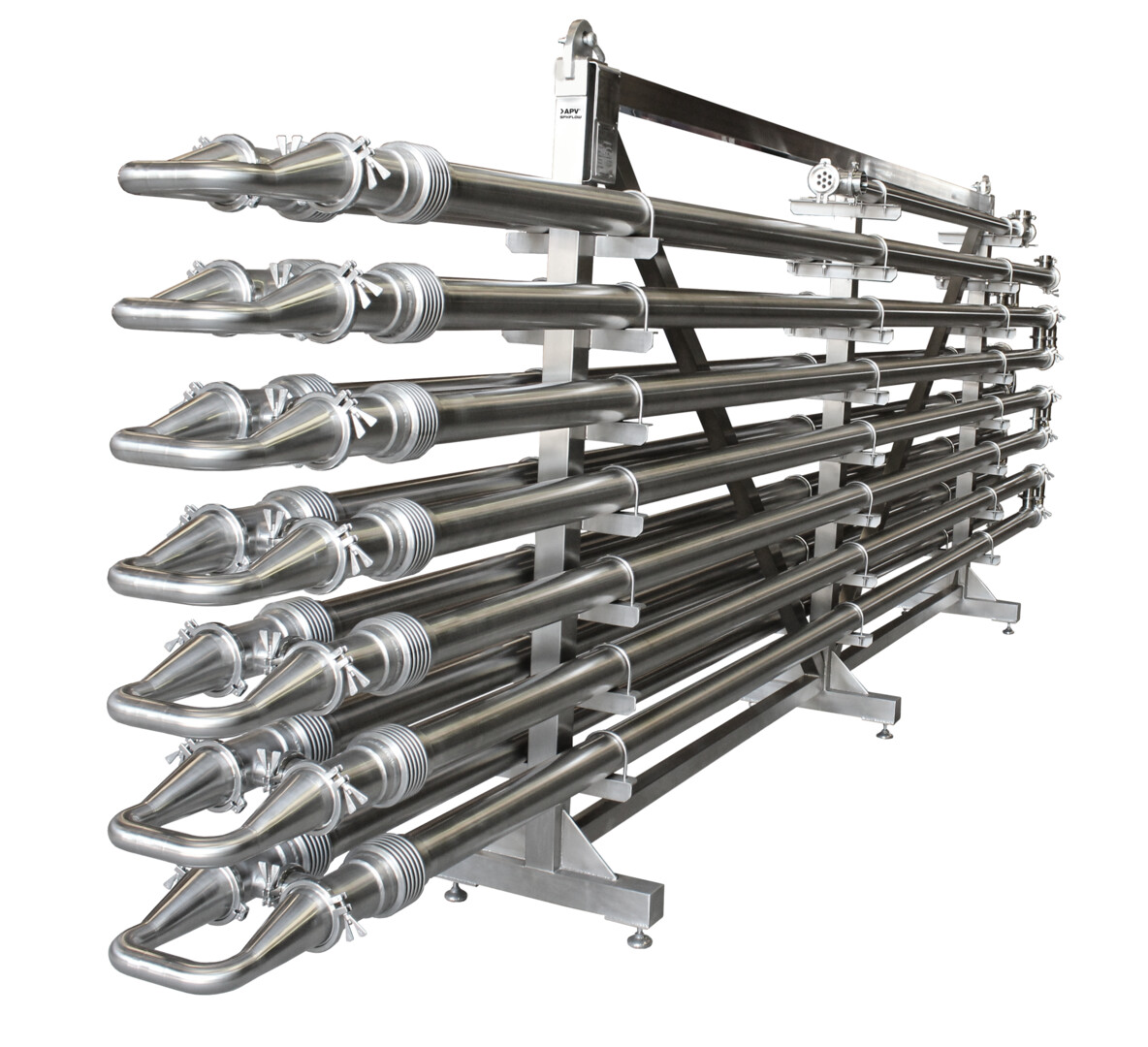

APV ParaTube Tubular Heat Exchangers are designed specifically for food applications with particles, ensuring gentle yet efficient heat transfer to preserve product integrity and quality.

Tubular Heat Exchanger Solutions

Designed for Your Process Needs

- Long runtimes

- Easy to clean

- Minimal maintenance

- Robust, reliable operation

- Handles challenging process fluids including medium to higher viscosity products with large particulates

How Tubular Heat Exchangers Work

A tubular heat exchanger (THE) is used to warm or cool a product by exchanging heat between the process fluid and a service fluid, which is typically water, ice water, glycol or steam. The hot or cold service fluid flows around the tubes within the THE and heat is transferred between the product and the media.

Optimizing Performance Through Custom Configuration

The rate of heat transfer is dependent on the tubular heat exchanger configuration, temperature differential, size of tubes, turbulence in the flow and flow velocity. Different configurations are available, and the selection of the best solution is based on the properties of the process fluid and production goals. Our experience and expertise will help ensure you receive the best solution for your specific needs in terms of production goals, costs, efficiency and product quality.

Tubular heat exchangers are suitable for many applications and are commonly used for fluids with low to medium viscosity and smaller to large particles.

APV ParaTube Tubular Heat Exchangers are ideal for:

- Pulpy Juices

- Yogurts

- Cream Sauces

- Soups

- Jam

- Desserts

- Chocolates

- Fruit Purees

- Vegetable Purees

- Baby Food

- Beer

- Ice Cream

- Margarine

- Broth / Gravy

- Soft Drinks

- Soy Milk

- Sterile Water

- Syrups

- Tea

- Vegetable Oil

- Whey

- Wine

- Milk

- Eggs

- Fresh Cheese