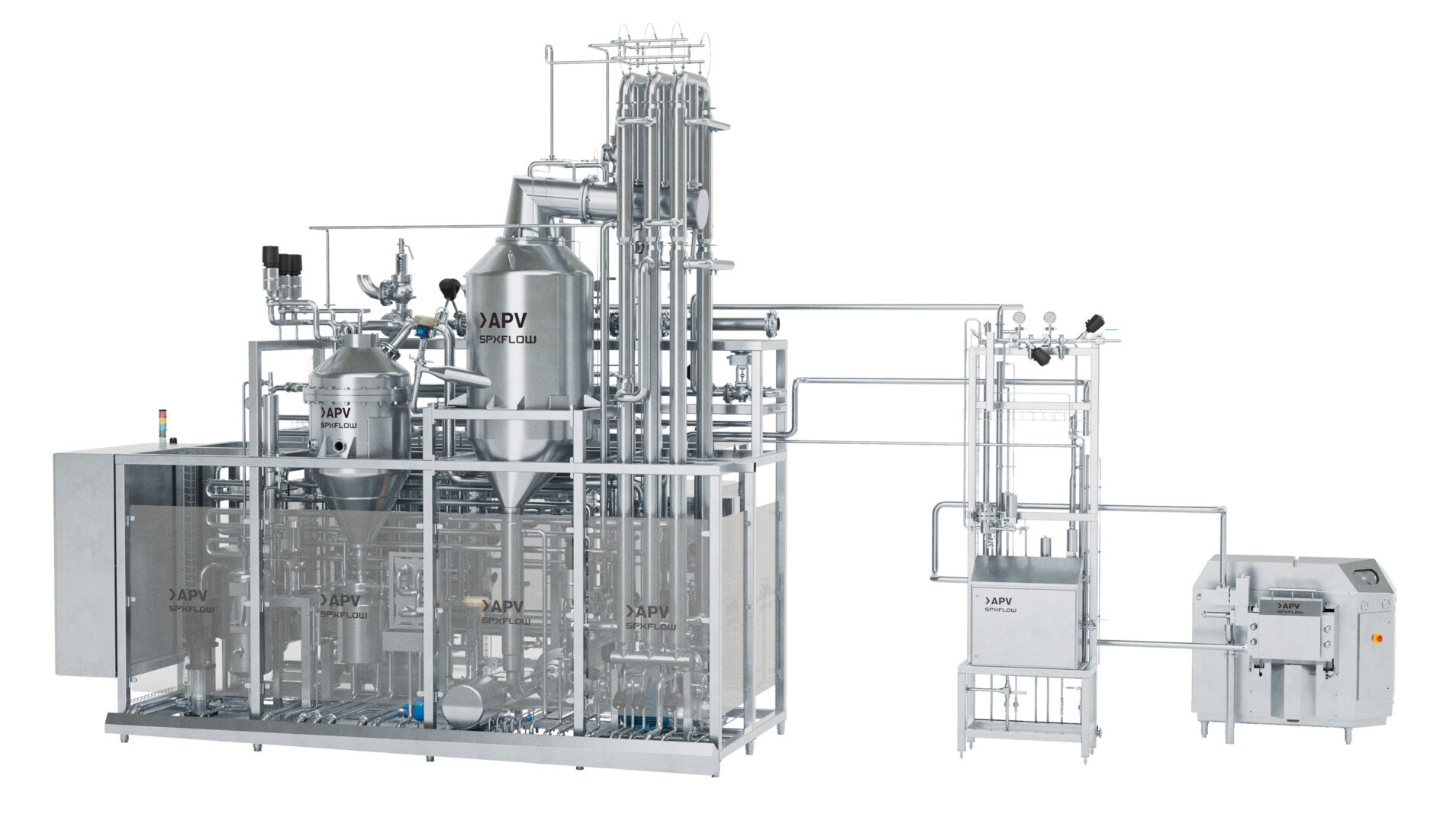

Infusion UHT Systems

The APV® Infusion UHT Systems are designed to deliver premium-quality aseptic and extended shelf life (ESL) products with minimal thermal impact through direct steam infusion. Using gentle, rapid heating and cooling with precise holding times, these systems ensure superior product integrity while preserving natural flavors, textures and nutrients. Engineered for dairy, plant-based beverages and high-protein applications, APV® Infusion UHT technology achieves fresh, pasteurized-like taste while extending shelf stability equal or better than standard HTST processed milk

APV® Infusion UHT Systems

Unmatched Freshness, Efficiency, and Flexibility

APV® Infusion UHT Systems deliver premium-quality aseptic and extended shelf life (ESL) processing with precise heat treatment through direct steam infusion and controlled temperature profiles. Compared to traditional UHT systems, it better preserves taste, texture, and nutrients while ensuring product safety.

Direct Steam Infusion Process

This patented technology has the ability to rapidly heat products to 157°C in just 0.09 seconds, achieving high bacterial spore kill rates while minimizing thermal degradation.

Taste and Quality Preservation

Using free-falling strings in a precisely controlled chamber, this process:

- Eliminates harmful microorganisms

- Ensures optimal heat penetration

- Preserves nutrients and flavors for a fresh, pasteurized-like taste

Infusion UHT milk has a distinct taste profile, with a fresher, more natural taste than traditional UHT and pasteurized milk. Its high-temperature, short-time process—where milk is rapidly heated and flash-cooled—minimizes thermal damage for superior quality.

Why Choose APV® Infusion UHT Systems?

Versatility and Efficiency

Developed through decades of innovation, APV® Infusion UHT technology is trusted worldwide for processing a wide range of viscosities, from milk and plant-based beverages to high-protein drinks and custards. Its customizable configurations and energy-efficient design make it the ideal solution for sustainable, high-performance production.

- Extended Shelf Life – Achieve up to six months of ambient storage for aseptic products.

- Fresh Taste Preservation – Maintain superior product quality with minimal chemical change and a fresh pasteurized milk flavor.

- Optimized Energy Efficiency – Lower operational costs with integrated energy recovery systems.

- High Processing Flexibility – Handle a wide range of viscosities, from low-viscosity beverages to thick custards and sauces.

Operational and Regulatory Benefits

- Low fouling rate – Enables longer production runs between Cleaning-in-Place (CIP) cycles

- Operator-friendly Design – Ensures easy operation, monitoring and maintenance

- Pre-Assembled and Factory-Tested – Delivers reliable performance and faster startup

- Regulatory Compliance - Optionally designed to FDA,3A and EU standards for global markets

- Comprehensive Support & Services – Includes customized SPX FLOW service agreements and global delivery of genuine spare parts and lifecycle service support.

- Innovation & Process Development – Leverage SPX FLOW’s global Innovation Centers to optimize recipes, enhance efficiency, and accelerate product development.

Innovation Support

SPX FLOW offers three Infusion UHT configurations, each designed for specific product characteristics and operational goals.

| Shelf Life | Storage | Application | Taste Profile | |

|---|---|---|---|---|

| Pasteurized Milk | 5 to 10 days | Refrigerated | Milk | Fresh taste |

| Infusion UHT | 3 to 6 months | Ambient | Milk, plant-based | Close to fresh taste |

| InfusionPlus™ UHT | 20 to 45 days | Refrigerated | Milk, protein drinks | Fresh taste |

| Instant Infusion | Pre-process | Ambient | Higher viscosity products including baby food and milk concentrate (up to 58% TS) for spay drying |

Infusion UHT Systems – Standard UHT Processing

The Infusion UHT Systems deliver premium-quality UHT processing through direct steam infusion, providing a smooth, controlled heat treatment with minimal thermal damage.

Best for:

- UHT milk and flavored milk

- Chocolate milk and yogurt-based beverages

- Cream and coffee whiteners

- Plant-based beverages (soy, oat, almond, etc.)

- Ice cream mix and custards

- Desserts (custards, puddings, vla)

- Sauces

Key Benefits:

- Rapid Heating to 143°C for 3 Seconds – Ensures efficient bacterial spore elimination while preserving taste and nutrients.

- Shelf Stability up to 6 Months – Provides extended ambient shelf life for aseptic products.

- Extended Run Time – Low fouling rates allow for longer production cycles before Cleaning-in-Place (CIP).

- Consistent Product Quality – Guarantees uniform texture, taste and microbiological safety.

InfusionPlus™ Systems – ESL with Fresh Taste

The patented InfusionPlus™ Systems enhance standard Infusion UHT technology with advanced heat recovery and ultra-fast heating, ensuring exceptional product quality and sustainability.

Best for:

- ESL milk and dairy

- High-protein drinks

Key Benefits:

- Ultra-Fast Heating to 157°C in 0.09 Seconds – Minimizes thermal stress, preserving fresh taste.

- Shelf Stability up to 45 days – Provides extended refrigerated shelf life for ESL products.

- Energy Savings – Advanced heat recovery systems reduce steam consumption and operational costs.

Instant Infusion Systems – High-Viscosity Products

The Instant Infusion Systems are designed for heat-sensitive, high-viscosity products requiring ultra-short heating times to maintain delicate flavors and nutrients.

Best for:

- Baby food

- Milk concentrates (for spray drying, up to 58% total solids)

- Whey protein concentrate

- Egg-based products

- Processed Cheese

Key Benefits:

- Fast heating: Heating rate of 600°C/sec.

- Ultra-Short Holding Time (0.09 Seconds) – Minimizes thermal impact while preserving product integrity and sensory qualities.

- Optimized for High-Solids Products – Processes viscous, protein-rich formulations while preventing fouling and scorching.

- Superior Nutrient Retention – Reduces vitamin loss by up to 70% compared to traditional UHT technology

- Extended Run Times – Operates for 20+ hours before requiring Cleaning-in-Place (CIP) maximizing production efficiency.

Contact SPX FLOW

Discover Your Ideal UHT Solution

Experience superior efficiency and premium quality with the Infusion UHT System. Contact SPX FLOW todayto learn how our technology can transform your aseptic and ESL processing.