Water is one of our planet’s most precious natural resources. Businesses around the world are looking for ways to reduce water usage in their operations. This is no different with businesses that employ homogenizers which can use up to 2 million gallons of water each per year to operate. But thanks to our new APV HWRS, 97% of that water can be recycled in a closed-loop water treatment system.

APV HWRS: Sustainable Water Recovery System

Smart Water Management for Homogenizer Operations

Homogenizers in typical continuous processing environments are cooled and lubricated by a supply of clean water which has traditionally been sent directly to the drain.

Regional Availability

The APV HWRS is a plug and play system that integrates with the homogenizer to virtually eliminate water use providing a sustainable and cost effective solution that helps conserve one of our planet’s most important natural resources.

The APV HWRS is initially available to customers in the Americas region.

Key Benefits

Water Reduction and Sustainability

- Recycles up to 97% of the water required by homogenizers

- Saves money by avoiding water cost increases

- Reduces exposure to water availability challenges

Process Quality and Control

- Meets or exceeds PMO Category I water standards

- Failsafe automation for continuous operation

- Integrated homogenizer leak detection

- Real-time water quality monitoring

- Built-in temperature regulation

Installation Flexibility

- Compatible with APV and other major homogenizer brands

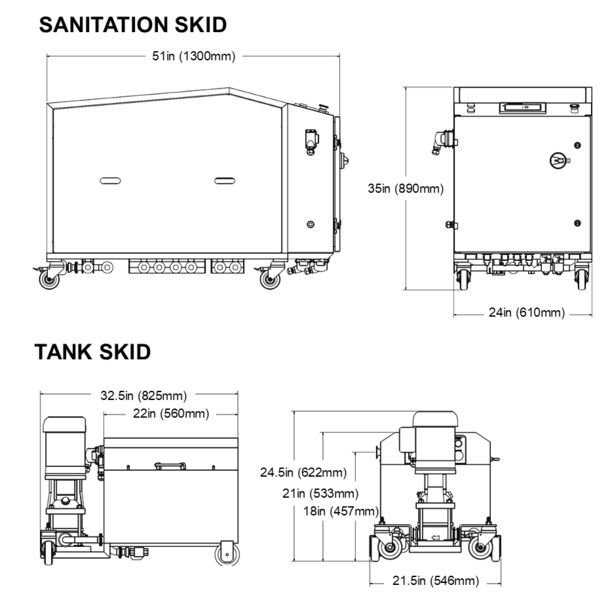

- Compact footprint

- Self-contained control architecture for plug-and-play integration