FEATURES

APV DualSafe™ Aseptic Mixproof Valve

Advanced Solution for Demanding Aseptic Processing

APV DualSafe™ Aseptic Mixproof Valve is designed to ensure aseptic processing in the most demanding environments. Our innovative solution combines advanced technology with meticulous design to ensure aseptic conditions, superior cleanability and uncompromising product quality and safety. Here’s what sets our valve system apart:

Maintain Aseptic Conditions

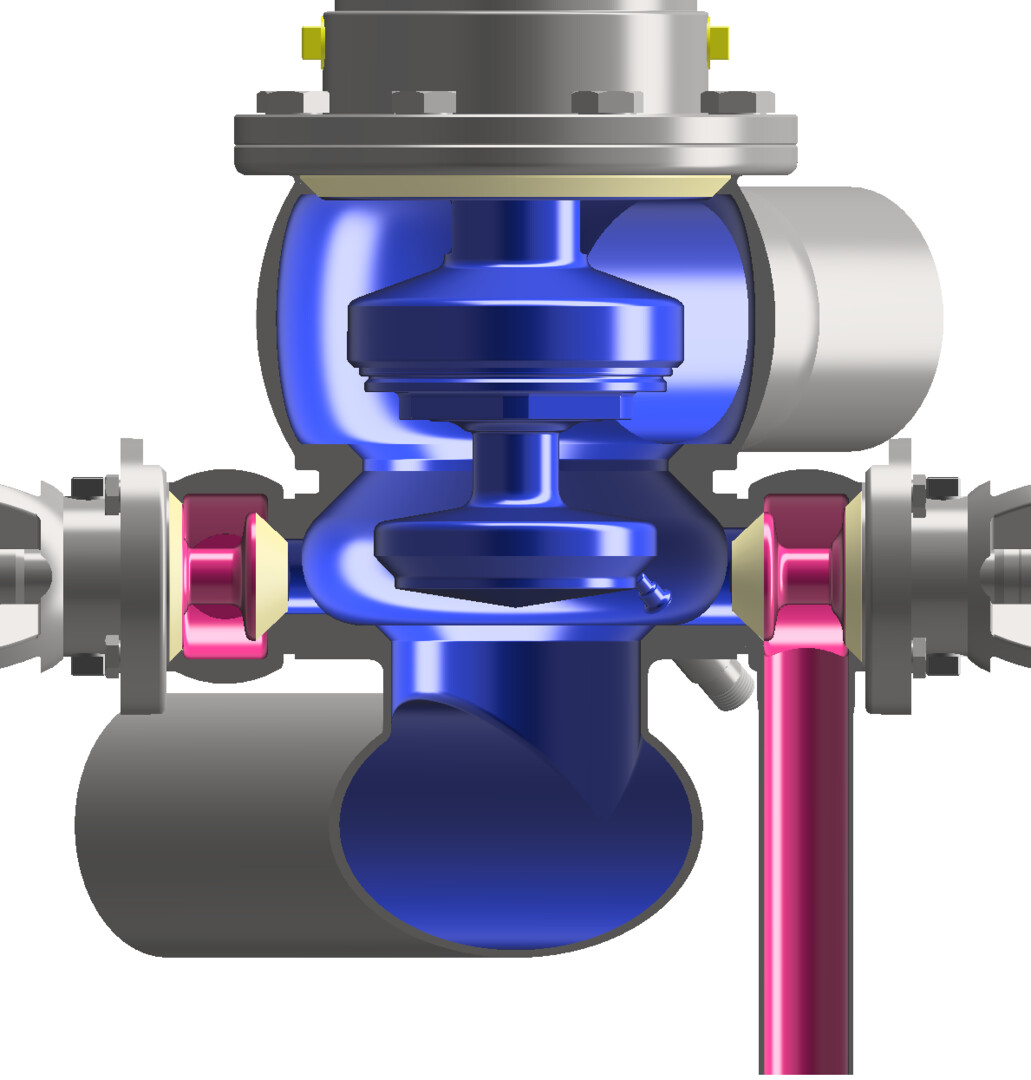

Proven Diaphragm Technology

Our valve system is built on a robust design principle that ensures aseptic conditions are maintained consistently by utilizing proven diaphragm technology. Two independent shafts effectively separate incompatible media, safeguarding the integrity of your products. Equipped with aseptic inlet and outlet valves, our system offers an extra layer of protection, ensuring that contamination risks are minimized, and product purity is preserved.

Enhanced Inlet and Outlet Protection

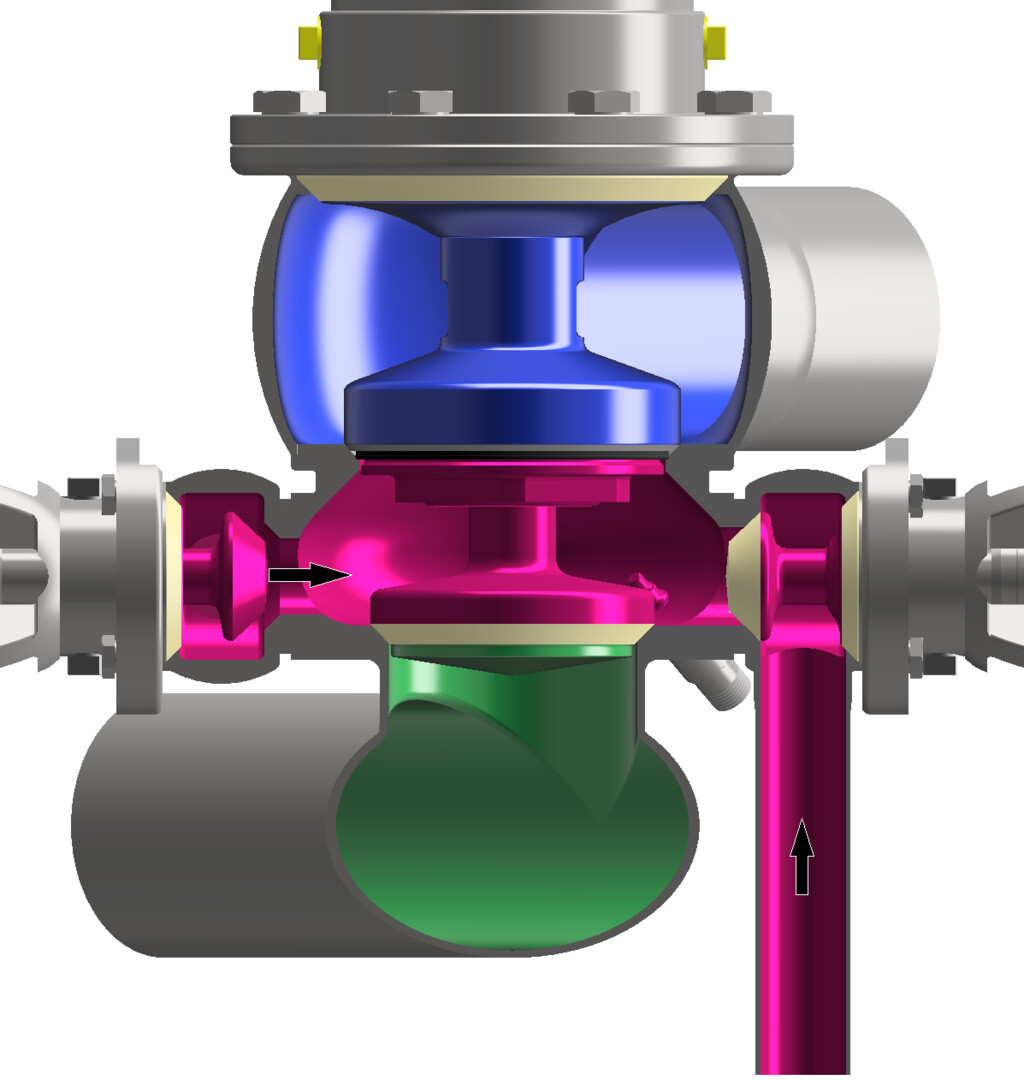

Improved Cleanability for Product Safety and CIP Consumption Reduction

Efficiency and cleanliness go hand in hand with our valve system, featured with independent seat lifting function and seat lift pulsation for thorough cleaning. This innovative design significantly reduces the consumption of Cleaning-In-Place (CIP) fluids. Key design elements include:

Improved Cleanability and CIP Efficiency

Smart Cleaning Design Features

- Upper Line without dome: Prevents air pockets, ensuring continuous velocity pattern for a comprehensive cleaning.

- Minimized Shadow Areas: Reduces hard-to-clean zones within the flow area.

- Optimized Flow: Computational Fluid Dynamics (CFD) optimized flow in valve housings ensures efficient and thorough cleaning.

- PTFE Diaphragm: Featuring no convolutions, the PTFE diaphragm presents a much smaller surface area compared to other solutions, enhancing its cleanability. PTFE’s superior cleaning properties further ensure high hygiene standards are maintained.

Product Quality and Safety Standards

Thermal and Microbial Protection

- Thermal Protection: PTFE diaphragms are designed to reduce thermal transfer, preserving the quality of temperature-sensitive products.

- Surface Finish: With a surface roughness of less than 0.8µm and e-polished housing, our system minimizes microbial adhesion, ensuring a high level of hygiene.

- Temperature Monitoring: A standard protection tube in the steam chamber allows for precise temperature sensor installation, ensuring accurate monitoring and control.

- Certified Materials: All product contact metal items come with a 3.1 certificate, including heat numbers, guaranteeing traceability and compliance with industry standards.

- 3A Design: Our valve system is designed to meet 3A sanitary standards, providing peace of mind regarding product safety.

Why Choose APV DualSafe™?

Efficient, Safe, and Reliable Performance

Choose our valve system for a cutting-edge solution that ensures aseptic conditions, enhances cleanability, and upholds the highest standards of product quality and safety. With our advanced technology and innovative design, you can trust that your processes will be efficient, safe, and reliable.