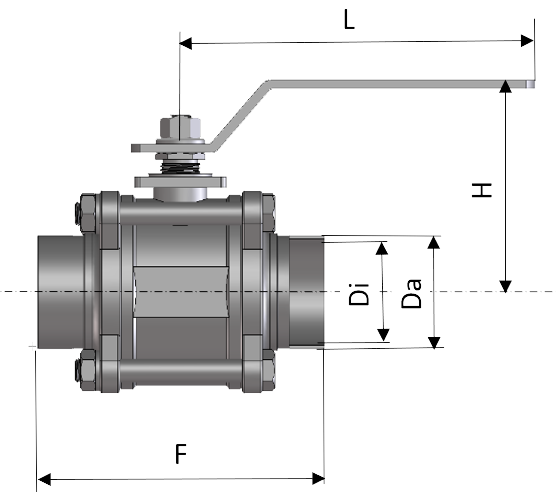

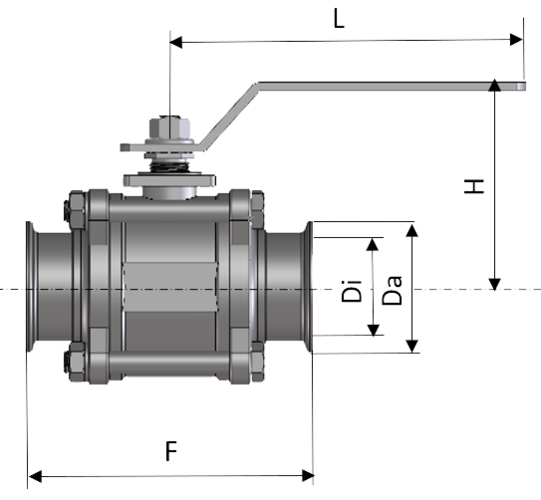

Sanitary Stainless Steel Ball Valve

Design and Construction Features

- All stainless-steel body and ball—forged for durability

- Three-piece design with floating seals

- Cavity-filled body prevents residue accumulation

- Full port opening ensures unrestricted flow

- Standard ISO mounting pad enables easy actuator retrofit

Material and Compliance

- FDA-approved construction materials

- Reinforced PTFE seats ensure reliable sealing

Performance Specifications

- Rated for high temperature and pressure service conditions

- Maintenance-free pneumatic actuator options:

- Normally Closed

- Normally Open

- Double Acting

Operational and System Integration Benefits

- Lockable manual handle for enhanced security

- Compatible control units align with other valve types for a unified interface and shared spare parts