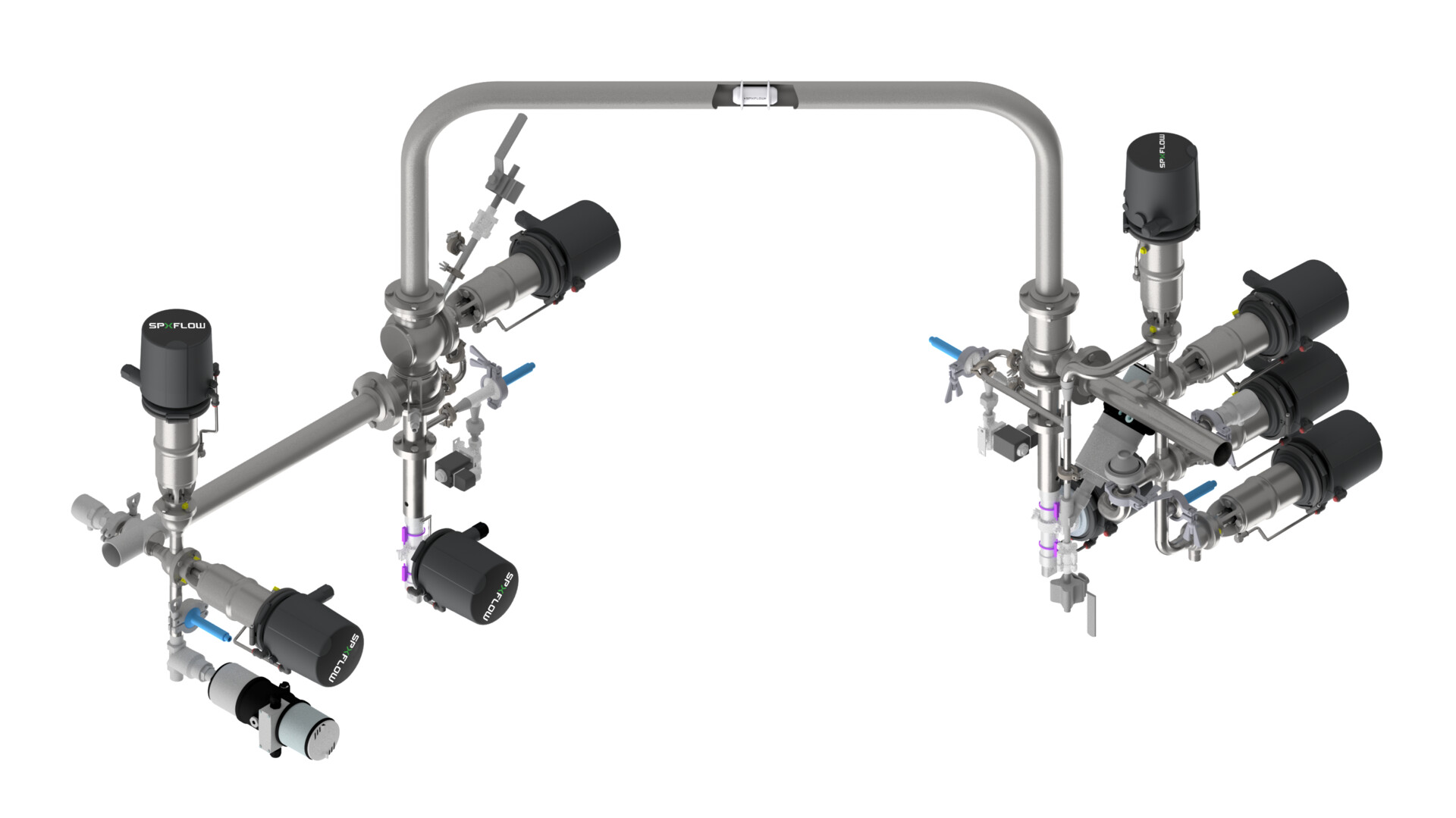

Aseptic Pigging System

Series : 54321

The award-winning APV Aseptic Pigging System (ARRS) efficiently recovers product from process pipes requiring stringent hygiene and sterile conditions, ensuring high food integrity. The system provides a sustainable solution that increases productivity, reduces waste, and enhances product yields. It is widely used in manufacturing lines for extended-shelf-life (ESL) products and long shelf-life products, such as yogurts and desserts, as well as plant-based alternatives, ice cream and some types of personal care products.

FEATURES

High-Performance Sterile Product Recovery

The award-winning APV Aseptic Pigging System is engineered for exceptional product recovery in extended shelf life (ESL) and long shelf-life product lines. This advanced system ensures minimal product loss, superior hygiene, and efficient cleaning-in-place (CIP), making it ideal for sensitive and high-value products.

This system minimizes product loss and enhances cleaning-in-place (CIP) processes, leading to improved production efficiency and sustainability. It complies with the highest hygienic standards, ensuring high food integrity. The APV Aseptic Pigging System can be fitted or retrofitted to any system and saves more high-value product than ever through a quicker cleaning process, leading to more up-time with less CIP. This also reduces chemical and water usage.

Highest Hygienic Standards, High Food Integrity

Aseptic pigging is performed with steam barriers at required interceptions in launching and receiving stations. It produces a sterile process while providing control of the sanitary state by returning the pig in aseptic conditions for multiple uses.

Key Features:

- High Product Recovery: Provides up to a 70%* reduction in product loss compared to hygienic cleaning systems without the APV pigging system and optimizes recovery before Cleaning-in-Place (CIP), resulting in more uptime with less CIP.

- Superior Hygiene: Maintains sterile conditions to ensure product safety. No product bypass, electropolished housings for better cleanability, and precise pressure control.

- Sterile Operations: Uses steam barriers and positive pressure to maintain aseptic conditions.

- Increased uptime: Due to faster cleaning methods, it provides more runtime compared to food processing plants without the APV pigging system.

- Certified Materials: CE marked, FDA, and EU food contact certified materials.

- Sustainable Design: Minimizes water and CIP chemical usage by up to 70%* due to less product soil to be washed out of the pipes.

- Easy to use and maintain: It can be retrofitted into existing systems and is optimized for maintenance using SPX FLOW spare parts, simplifying maintenance and operation.

*Figures are contingent on actual running conditions within the plant.

Why Choose APV Aseptic Pigging System?

- By Design: Ensures no product bypass and precise pressure control.

- By Construction: Electropolished housings for easy cleanability.

- By Material: Certified for FDA and EU food contact.

- Functionality: Optimized for high-efficiency product recovery and minimal waste. Uses steam barriers and positive pressure for aseptic conditions throughout the production run.

Applications

- Any liquid and viscous products

- Chocolate

- Cosmetics

- Cream with 40% fat and higher

- ESL and Long-life products, such as yogurt, cheese and other fermented products

- Desserts

- Ice cream

- Milk concentrates

- Nutraceuticals

- Neutral pH products

- Plant based applications