FEATURES

The UFMS4 aseptic pressure relief valve is essential for maintaining system sterility, particularly in environments where contamination poses significant risks. It is crucial in processes requiring a sterile environment, preventing contamination while relieving excess pressure.

Benefits:

Optimum cleanability

· No limitation on stroke due to seat lift actuator; full opening cross-section is available during cleaning

· 3-A approved and designed to EHEDG guidelines for hygienic operation

Minimize Operational Downtime

· Enhance control for improved response to pressure relief events; facilitated by proximity switches or control unit feedback

· All valves feature a seat lifting function to open the valve during cleaning operation reducing downtime

Optimize Process Efficiency

· Protects pumps with an external over pressure relief valve. If the pump discharge pressure exceeds the preset cracking pressure, the valve will open to provide a relief path.

· Choose from a range of options to standardize operations, available in nominal diameters from DN25 to DN100 and ISO 1” to 4

Features and Benefits:

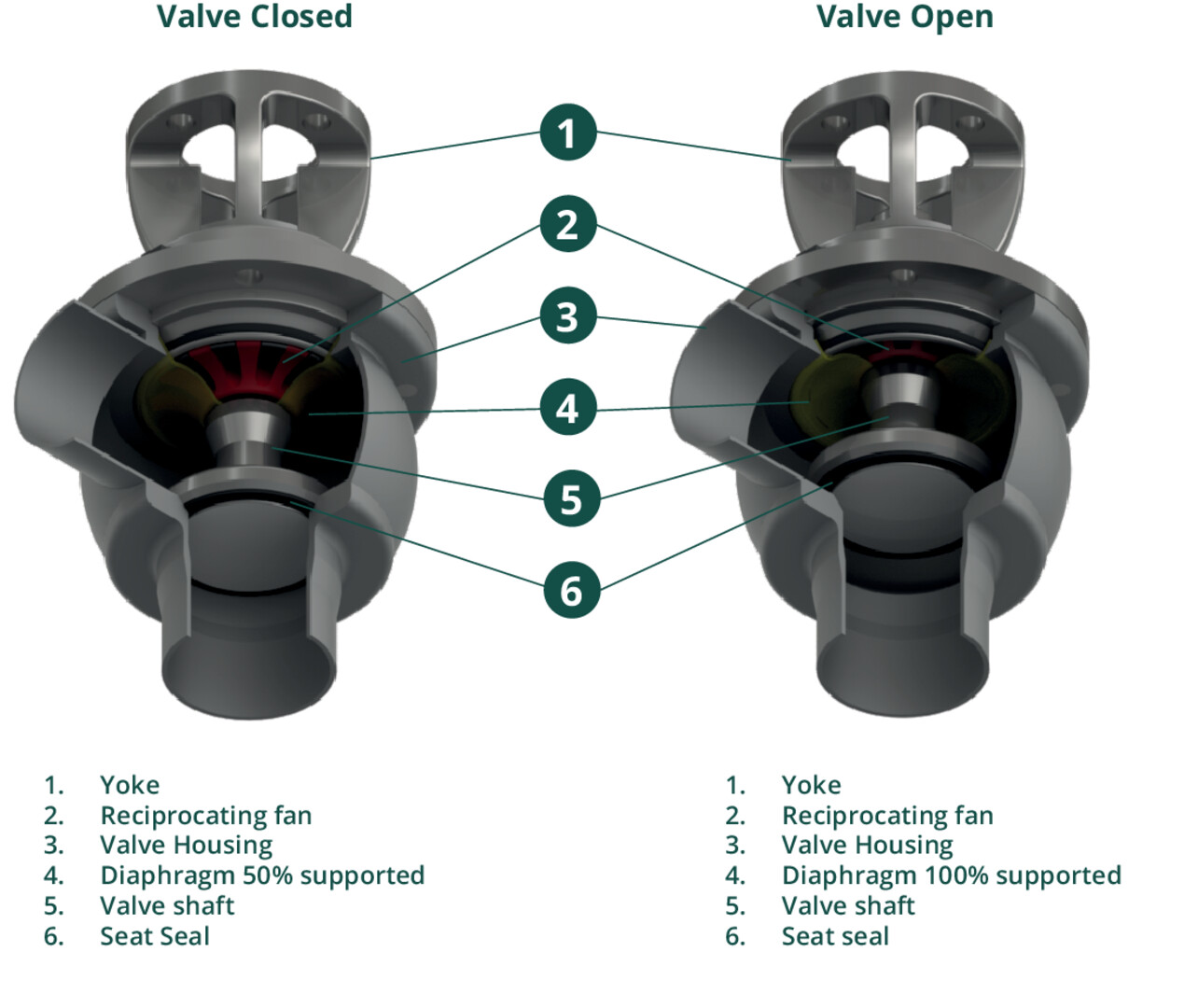

· Innovative fan support mechanism extends operating pressure range and diaphragm lifespan

· Standard seat lift actuator includes feedback switches for enhanced functionality

· Four different actuators enable a wide range of pressure settings

· Flat, easily cleanable single-layer diaphragm design allows for immediate leakage detection

· Suitable for process pressures of up to 145 psi (10 bar).

· High temperature capability.

· Easy and cost-effective maintenance compared with bellows provides lower cost of ownership.

· UFMS4 available with USP Class VI approved diaphragm and diaphragm shaft material.

· The metal stop ensures defined compression of the seat seal, reducing material stress.

· UFMS4 valves compatible with a comprehensive range of CU4 and CU4plus control units