Triple-A Spray Dryers

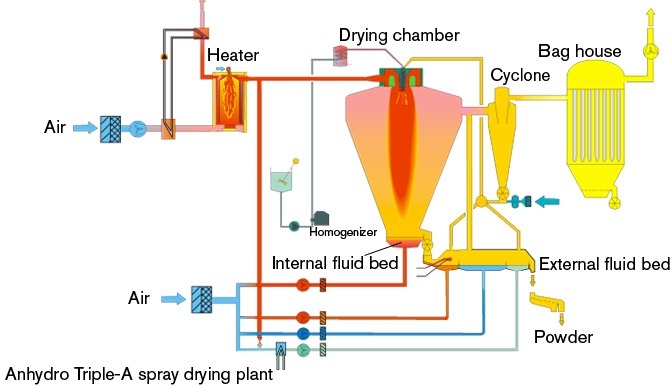

Anhydro Triple-A Spray Dryers enable powder manufacturers to design and customize a complete drying solution for the production of free-flowing, dustless powders and agglomerates based on customer specifications.