FEATURES

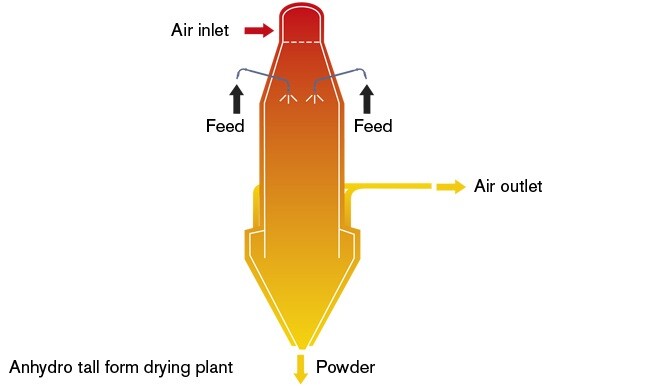

The feed is atomized at a low-pressure co-current to the drying air being introduced at the chamber top as a laminar flow.

The chamber has a large cylindrical section providing sufficient residence time for large particles to dry out under gentle conditions. The main part of the powder is discharged at the chamber bottom and can be further dried or cooled in an external fluid bed.

The fines are conveyed with the drying air to a separation system. Many tall form drying plants are provided with a bustle on the cylinder for the air outlet, minimizing the dust fraction of the powder.

The particle size is 300 - 800 microns.