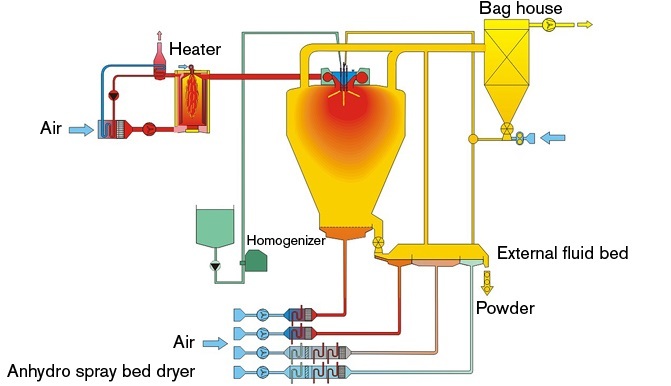

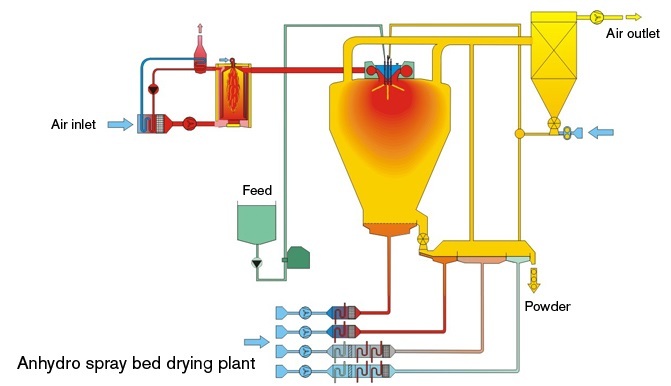

Spray Bed Dryers

Anhydro Spray Bed Dryers are used in the food, chemical and pharmaceutical industries to produce dust-free, agglomerated, dispersible and free-flowing powders. Our spray bed dryers are available in designs tailored to meet the specific requirements of each industry.

Configurations:

- Single-stage dryer

- Multi-stage dryer

- Closed-circuit dryer

Options: