Spin Flash Dryers

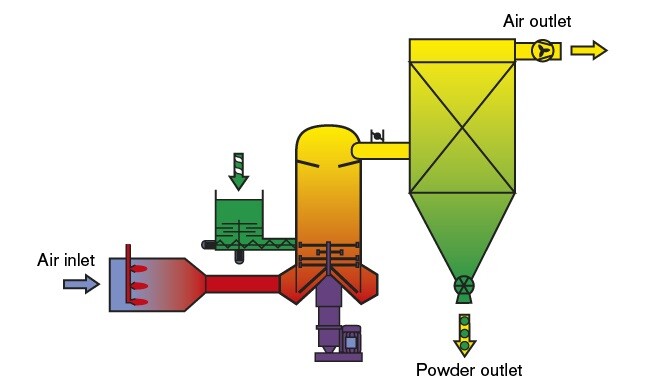

Anhydro Spin Flash Dryers are designed for the continuous drying of both cohesive and non-cohesive pastes, filter cakes and high-viscosity liquids. The main components of the spin flash plant include a feed system, a patented drying chamber and a bag filter.

Configuration:

- Closed-circuit dryer