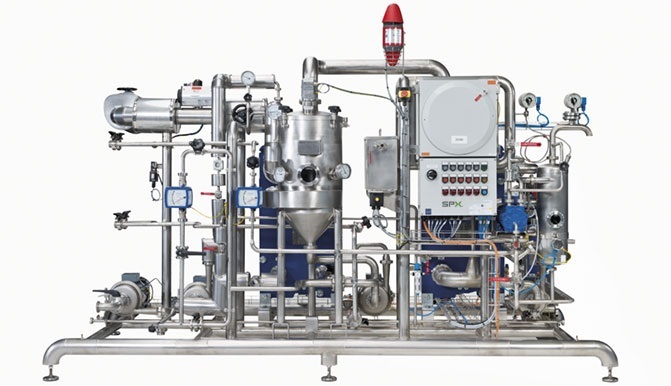

Pilot Evaporation Plants

FEATURES

The SPX FLOW pilot plate evaporation plant is designed to concentrate small batches of extracts or other liquid products based on water or ethanol solvent. For other organic solvents (chlorinated), the sealing material has to be adapted. The concentration rate is limited to the viscosity of the concentrated liquid up to approx. 500 cP. The plant is used for the concentration of watery or organically dissolved extracts. The plant consists of a plate evaporator with a downstream centrifugal separator. The evaporated vapors are condensed in a plate condenser. A vacuum pump is connected to the condenser, and the vacuum can be adjusted between 20 and 800 mbar.

The evaporation temperature can be adjusted according to the product specific boiling curve through the applied vacuum. By this, even temperature sensitive extracts can be concentrated.

Advantages

- Determination of all process conditions which are necessary for the design and the purchase of a production plant, as for example product quality, evaporation behavior, temperature sensitiveness, etc.

- Quick availability of the plant

- It is possible to rent the plant for several months

- Commissioning and training of the operator personnel by specialists

- Consultancy by specialists: before, during and after the test runs

- Only little space will be required for the installation of the plant